robot

-

Hot

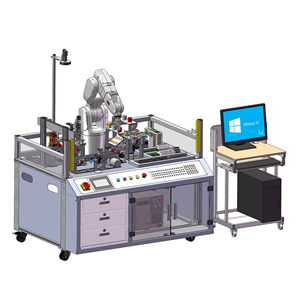

Digital twin training system

DLIM-DT01B Digital twin technology application platform Using digital twin technology application platform, a virtual simulation system with actual interactive function is created according to the requirements. The simulation system can realize the physical performance, mechanical structure and action function consistent with the actual environment. It can make the mechanical design and electrical design develop in parallel on the simulation system, and eliminate the gap period in the traditional development process. The simulation system is not only a simple animation scene, but also can interact with the actual control equipment, receive control instructions and feedback signals from sensors, etc. during the simulation process, it can timely discover various problems in the operation of the equipment under program control and carry out optimization, so as to improve the design efficiency and reduce the cost and risk. In response to the above situation, the State Council issued notice on Issuing the plan for the implementation of the national vocational education reform (Guo Fa [2019] 4), pointing out that we should adapt to the development demand of "Internet plus occupation education", improve the teaching methods and methods with modern information technology, and promote the construction and application of virtual learning network occupation space, and complement and expand the offline practical training teaching activities.

vocational education vocational training system international cooperation indsutrial 4.0 training systemEmail Details -

DLDS-3512 Industrial Robot Technology Application System With KUKA Robot And Siemens 1200PLC+AI (Dolang Student)

Complete the transmission, identification, assembly, inspection and warehousing tasks of various integrated training module products It is divided into five training modules, namely: fingertip gyro press module, digital keyboard automatic assembly module, workpiece automatic grinding module, robot automatic gift packaging module, multi-variety material transfer and palletizing module

Email Details -

DLDS-3512 IR4.0 Industrial Robot Technology Training system Vocational Educational Equipment+AI (Dolang Student)

Through the system platform software, you can set the action speed, direction and other parameters involved in the task execution process; such as the setting of the angle, speed and acceleration and deceleration time of the servo motor of the assembly turntable platform; the AGV transmission trolley route setting and action programming.

Email Details -

DLDS-3512 Industrial Robot training System With ABB Robot And PLC training kits of TVET equipment +AI (Dolang Student)

The training module is composed of the corresponding raw material warehouse, finished product warehouse, conveying mechanism and tooling fixture; in the training of different assembly tasks, only the corresponding training module needs to be installed on the operating platform.

Email Details -

DLIR-113 Industrial Robot Basic Skills Training Equipment of robot training system

The platform integrates the latest technology in the field of industrial robots, allowing students to learn the most advanced industrial robot application technology

Email Details -

DLIR-174 Industrial Robot Operation and Programming Application System

The skills students can learn and master using this platform include sensor detection technology, visual detection technology, electrical control technology, stepper drive technology, servo drive technology, industrial robot technology, PLC technology, configuration technology, production line process design, system maintenance and Fault detection technology, offline programming simulation technology, industrial Ethernet communication technology, etc.

Email Details -

DLDS-1190 Industrial Robot Comprehensive Training System

The DLDS-1190 training system is equipped with FANUC industrial robot, SIEMENS PLC. It is equipped with the vision system (2D) of the FANUC intelligent camera, a unit of machining automation task, a basic operation assessment module, a gift packaging task unit, an intelligent transfer-sorting-palletizing task unit, a digital keyboard assembly task unit, a process application welding task unit, components, etc.

Email Details -

DLIM-732 Service Manufacturing Technology Platform(Industry 4.0 Training System)

Equipment composition and function description: Device workflow: 1) Data management unit: order management and data display 2) Automatic feeding unit: According to the requirements, the workpiece is pushed out of the bin by the feeding cylinder, and the handling manipulator transports the pushed workpiece to the conveyor belt of the sorting unit, and scans the workpiece bottle for inspection. 3) Intelligent sorting unit: The conveyor belt transports the workpieces of the previous station to the stop position, and completes the canning of 5mm or 8mm steel balls according to the order requirements. The gear stop mechanism resets, and the finished workpiece enters the next workstation.

Email Details -

DLIM-WL08 Logistics Management System(Industry Robot)

DLIM-WL08 logistics management system, through the network interconnection, data intercommunication and system interoperability of industrial resources, realizes the flexible ways of warehouse customization, material order storage, selection of storage, upper storage and lower storage, and material storage. The process is carried out according to the selected method, and the reasonable optimization of the logistics system enables the efficient use of resources, thereby building a high-efficiency, high-precision, and high-standard logistics management system.

Email Details