DLDS-3512 Industrial Robot training System With ABB Robot And PLC training kits of TVET equipment +AI (Dolang Student)

- Dolang

- China

- 30-60 days

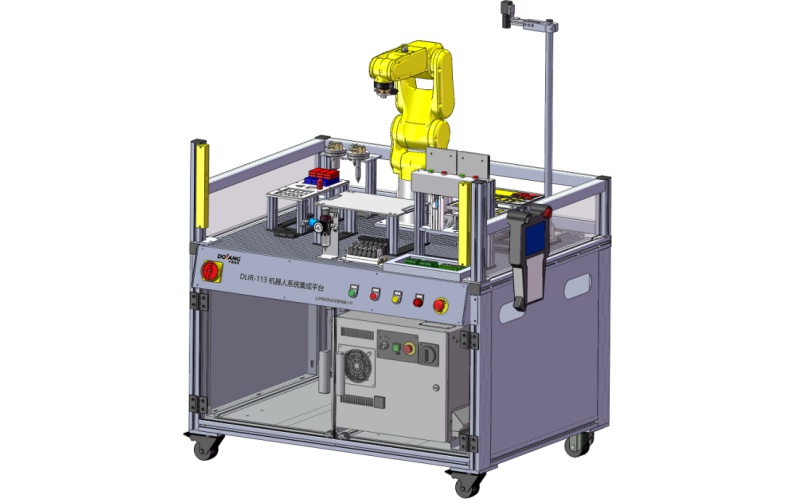

The training module is composed of the corresponding raw material warehouse, finished product warehouse, conveying mechanism and tooling fixture; in the training of different assembly tasks, only the corresponding training module needs to be installed on the operating platform.

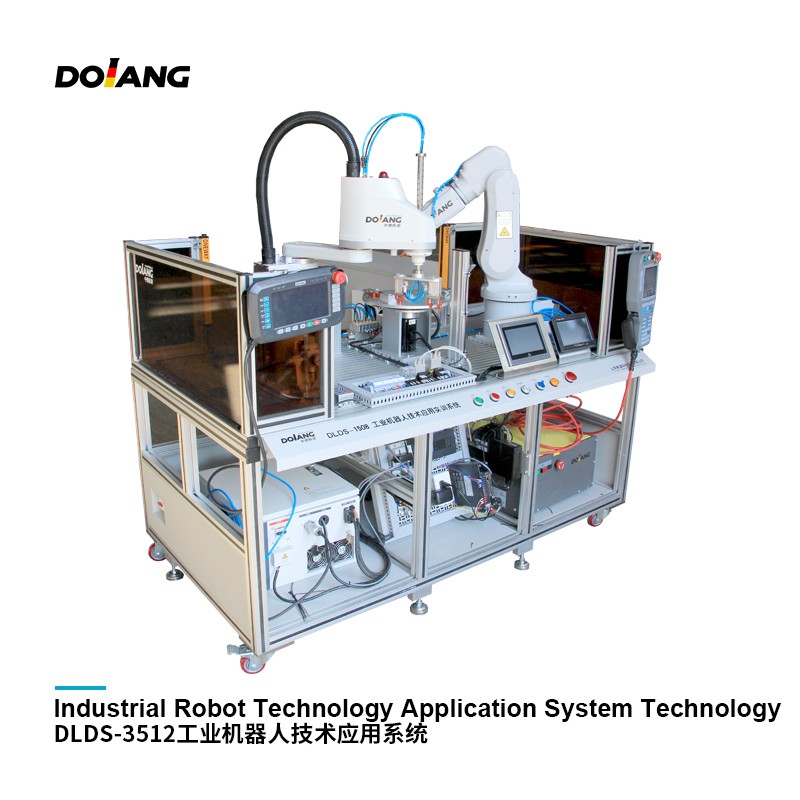

DLDS-3512 Industrial Robot training System With ABB Robot And PLC training kits of TVET equipment +AI (Dolang Student)

Equipment Overview

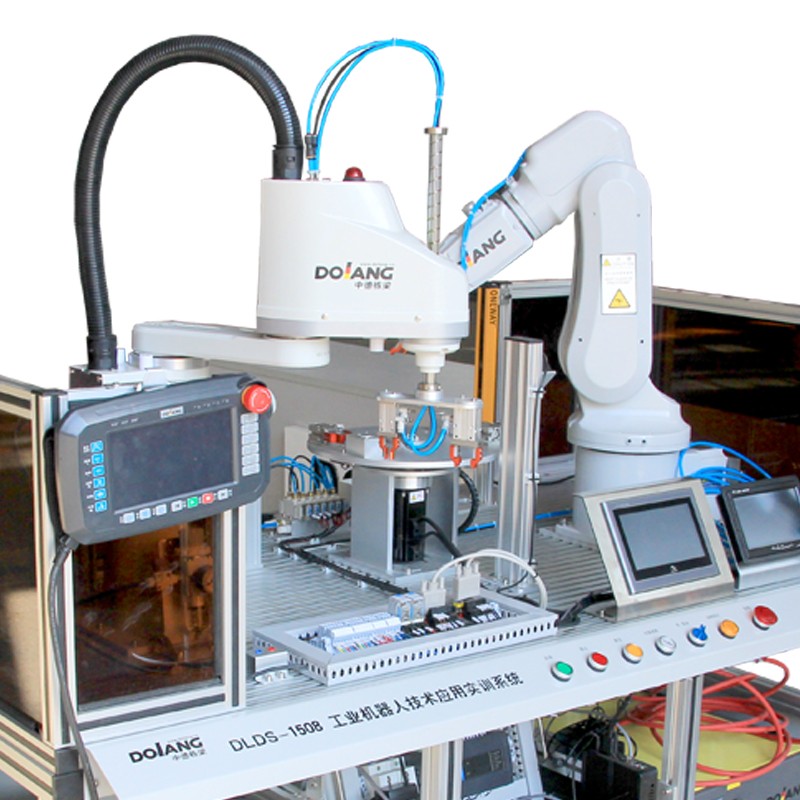

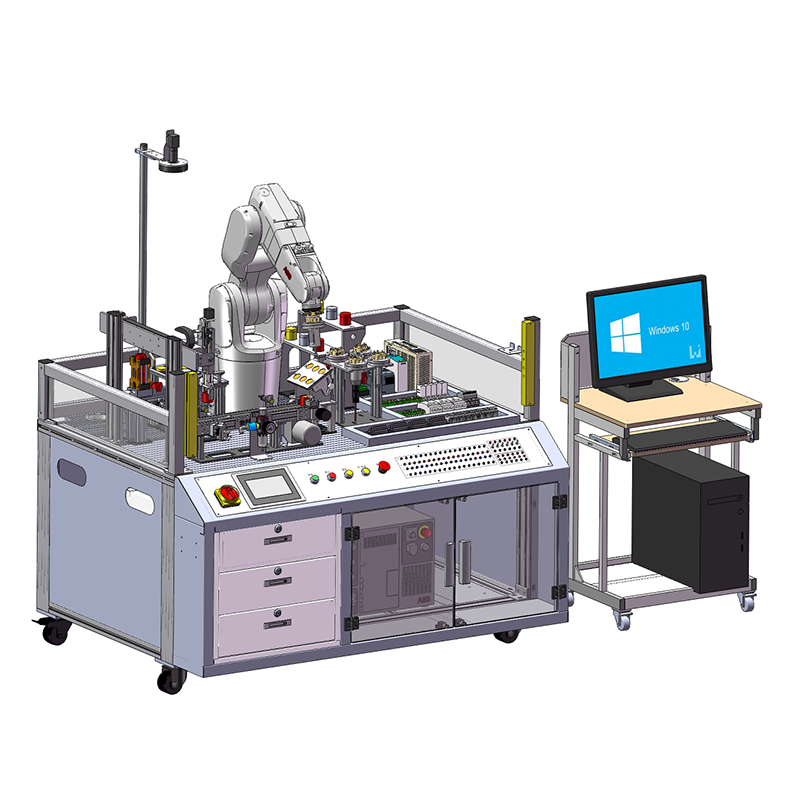

The DLDS-3512 Industrial Robot training System With ABB Robot And PLC training kits of TVET equipment adopts a modular and open design, and consists of a basic industrial robot training platform and an integrated training module; among them, the basic industrial robot training platform is mainly composed of six-axis robots, four-axis robots, industrial vision cameras, mobile conveyor systems, and PLCs. Control unit, touch screen, etc. The main function is to complete the transmission, identification, assembly, inspection and storage tasks of various integrated training module products; the integrated training module is divided into five training modules according to the different assembly tasks, namely: Pointed top pressing module, digital keyboard automatic assembly module, workpiece automatic grinding module, robot automatic gift packaging module, multi-variety material transfer and palletizing module. Among them, the training module is composed of the corresponding raw material warehouse, finished product warehouse, conveying mechanism and tooling fixture; in the training of different assembly tasks, only the corresponding training module needs to be installed on the operating platform.

Technical Parameters

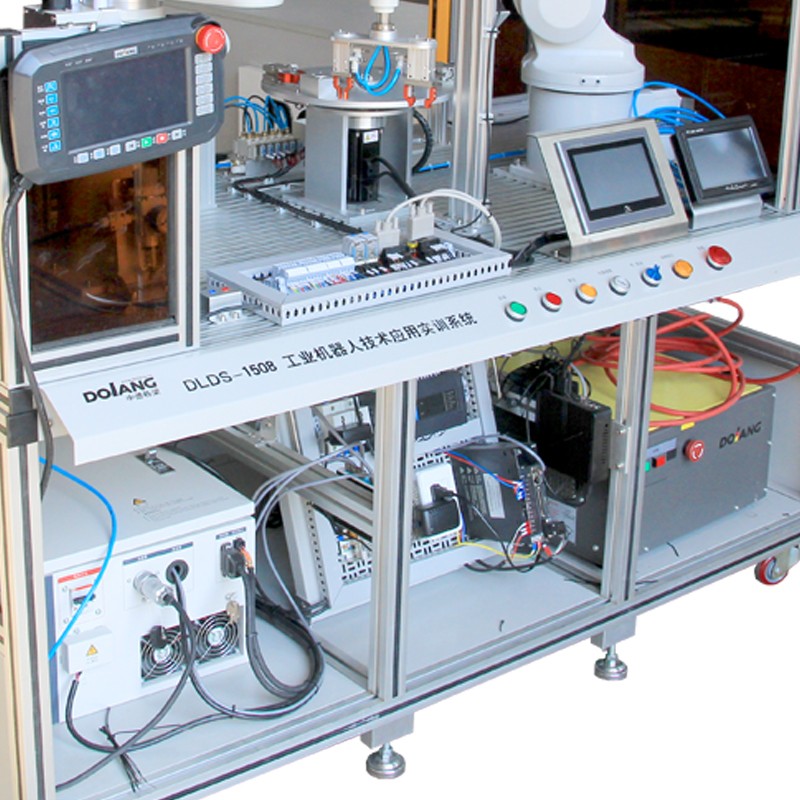

(1) Input power: single-phase three-wire AC220V±10% 50HZ,

(2) Working environment: temperature -10℃-+40℃, relative humidity <85% (25℃), no condensation of water drops above sea level <4000m

(3) Output power: DC regulated power supply: 24V/3A.

(4) Equipment size:

1#Operating platform: 1700*1000*1600 (L*W*H)

2#Operation platform: 1700*950*1200 (L*W*H)

(5) Safety protection function: short circuit protection, overload protection, emergency stop protection, etc.

(6) Touch screen: 7 inches

(7) Six-joint industrial robot uses ABB six-axis

Training Content

(1) Fingertip gyro press-fitting production tasks based on robot automatic loading and unloading

(2) Fully automatic assembly task of numeric keyboard

(3) Work task of automatic grinding of workpiece

(4) Robot automatic gift packaging task

(5) Multi-variety material transfer and palletizing tasks

Testable knowledge and skill points

(1) Understanding and application of six-axis robots

(2) Six-axis industrial robot installation

(3) Installation and application of four-axis industrial machines

(4) Four-axis robot training and calibration

(5) Six-axis robot training and calibration

(6) AGV recognition and application

(7) Assembling and debugging the mechanical structure of the transmission mechanism

(8) Compilation of motion control program for assembly, inspection and transmission mechanism

(9) Assembly and debugging of mechanical structure of visual inspection module

(10) Electrical debugging of visual inspection module

(11) Assembly, installation and commissioning of finished product warehouse

(12) Installation of cutting process simulation device

(13) Application of robot and PLC communication

(14) Application of detection switch

(15) Application of multiple sensors

(16) Application of pneumatic components

(17) Application of PLC

(18) Application of visual man-machine interface

(19) Gas circuit and circuit construction

(20) Assembly and disassembly of mechanical parts

(21) System fault diagnosis and maintenance

AI system application

22) AI-based PLC basic instruction practice

23) AI-based PLC and digital twin linkage programming

24) AI-based industrial robot and visual communication training

25) AI-based voice control industrial robot training

26) AI-based voice generation industrial robot program training

27) AI-based voice control industrial robot program training

FAQ

Q1. What other services can Dolang provide besides teaching equipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.