Digital twin training system

- Dolang

- Jinan

- 60 days

- 100 units per year

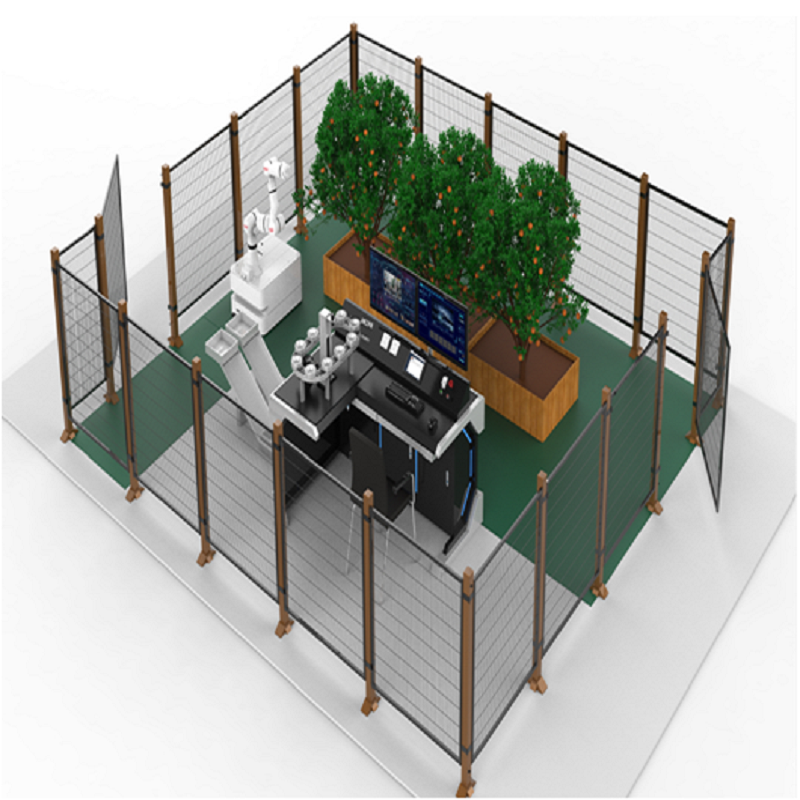

DLIM-DT01B Digital twin technology application platform

Using digital twin technology application platform, a virtual simulation system with actual interactive function is created according to the requirements. The simulation system can realize the physical performance, mechanical structure and action function consistent with the actual environment. It can make the mechanical design and electrical design develop in parallel on the simulation system, and eliminate the gap period in the traditional development process.

The simulation system is not only a simple animation scene, but also can interact with the actual control equipment, receive control instructions and feedback signals from sensors, etc. during the simulation process, it can timely discover various problems in the operation of the equipment under program control and carry out optimization, so as to improve the design efficiency and reduce the cost and risk.

In response to the above situation, the State Council issued notice on Issuing the plan for the implementation of the national vocational education reform (Guo Fa [2019] 4), pointing out that we should adapt to the development demand of "Internet plus occupation education", improve the teaching methods and methods with modern information technology, and promote the construction and application of virtual learning network occupation space, and complement and expand the offline practical training teaching activities.

DLIM-DT01B Digital twin technology application platform

Overview

At present, the digital wave represented by the Internet of things, big data, artificial intelligence and other new technologies is sweeping the world. The physical world and the corresponding digital world are forming two systems, developing in parallel and interacting with each other. The digital world exists to serve the physical world, which becomes efficient and orderly because of the digital world. In this context, digital twin technology has become more and more widely used.

At the same time, as an indispensable link in the process of students' professional knowledge learning, skills mastering and literacy formation in technical engineering colleges and universities, more and more attention has been paid to it. In order to provide the carrier of practical teaching and learning activities, schools mostly carry out offline entity training rooms. However, the offline entity training room is limited by the site, equipment, funds and other restrictions, it is difficult to ensure that each student can achieve the training project type and training hours specified by the teaching.

Using digital twin technology application platform, a virtual simulation system with actual interactive function is created according to the requirements. The simulation system can realize the physical performance, mechanical structure and action function consistent with the actual environment. It can make the mechanical design and electrical design develop in parallel on the simulation system, and eliminate the gap period in the traditional development process.

The simulation system is not only a simple animation scene, but also can interact with the actual control equipment, receive control instructions and feedback signals from sensors, etc. during the simulation process, it can timely discover various problems in the operation of the equipment under program control and carry out optimization, so as to improve the design efficiency and reduce the cost and risk.

In response to the above situation, the State Council issued notice on Issuing the plan for the implementation of the national vocational education reform (Guo Fa [2019] 4), pointing out that we should adapt to the development demand of "Internet plus occupation education", improve the teaching methods and methods with modern information technology, and promote the construction and application of virtual learning network occupation space, and complement and expand the offline practical training teaching activities.

Training projects:

1. PLC programming and debugging

2. HMI configuration and debugging

3. Cognition and application of industrial robot teaching device

4. Off line programming and debugging of industrial robot

5. TCP / IP communication between PLC and six axis industrial robo

6. Application of visual technology

7. Construction and layout of digital 3D model

8. Industrial network communication and debugging

9. Mechatronics collaborative simulation: mechanical interference, mechanism kinematics verification, mechanism dynamics verification

10. Equipment automation joint virtual debugging: PLC program, HMI screen

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.