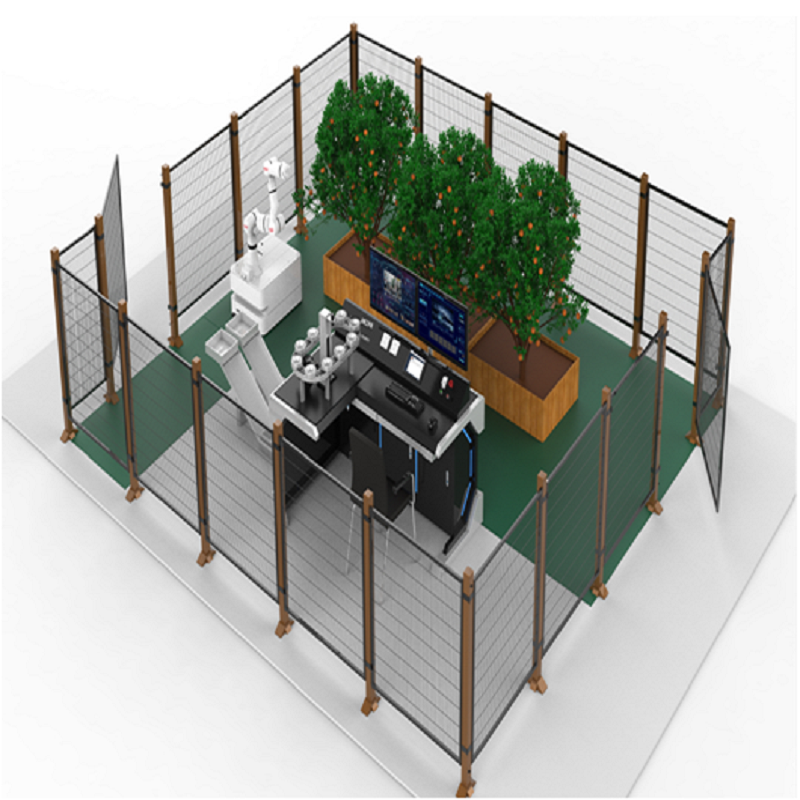

DLIM-732 Service Manufacturing Technology Platform(Industry 4.0 Training System)

Equipment composition and function description:

Device workflow:

1) Data management unit: order management and data display

2) Automatic feeding unit: According to the requirements, the workpiece is pushed out of the bin by the feeding cylinder, and the handling manipulator transports the pushed workpiece to the conveyor belt of the sorting unit, and scans the workpiece bottle for inspection.

3) Intelligent sorting unit: The conveyor belt transports the workpieces of the previous station to the stop position, and completes the canning of 5mm or 8mm steel balls according to the order requirements. The gear stop mechanism resets, and the finished workpiece enters the next workstation.

1. Overview

Equipment composition and function description:

Device workflow:

1) Data management unit: order management and data display

2) Automatic feeding unit: According to the requirements, the workpiece is pushed out of the bin by the feeding cylinder, and the handling manipulator transports the pushed workpiece to the conveyor belt of the sorting unit, and scans the workpiece bottle for inspection.

3) Intelligent sorting unit: The conveyor belt transports the workpieces of the previous station to the stop position, and completes the canning of 5mm or 8mm steel balls according to the order requirements. The gear stop mechanism resets, and the finished workpiece enters the next workstation.

4) Assembly testing unit: weigh the canned workpieces, and the three-color lights will display according to the weighing results (the yellow indicator light flashes in the weighing state, the green light is green after the quality inspection is passed, and the red flashes if the quality inspection fails). Re-qualified materials for material assembly.

5) AGV logistics unit: transport the workpieces of the assembly inspection unit to the intelligent storage unit.

6) Intelligent storage unit: transport the workpieces of the AGV logistics unit for storage.

This industry 4.0 system included following units:

1. Data management unit

2. Automatic feeding unit

3. Intelligent sorting unit

4. Assembling the detection unit

5. Storage robot

6. AGV logistics unit

7. Intelligent storage unit

8. Visualization system

9 Energy Management Module

10 network equipment

11 Electric control and communication system

12 Pneumatic system

13 software

13.1 PLC programming software

13.2 MES system

13.3 Digital twin simulation software

14 Zhuangliang Creation Cloud Platform

15 other

1) Tool kit: The tools include hexagonal wrench, slotted screwdriver, Phillips screwdriver, etc.

2) Teaching resources: Teaching resources include training instruction manuals and teaching resources related to sample programs.

2. Functional Features

1. Device selection: The main devices used in the platform are selected from international and domestic well-known brands, with advanced technology and high market occupancy.

2. Standardization: The platform is designed to be developed and tested in accordance with relevant national safety standards and specifications for machinery and electrical equipment.

3. The modular design conforms to the laws of teaching and students’ cognition. Teachers and students can choose different combinations of modules to practice according to the needs of teaching and competitions.

4. Personalized customization: Customers can place personalized orders through the industrial Internet cloud platform or APP, and choose the desired product type and product appearance.

5. Field bus: The field control equipment has communication function, which constitutes the bottom control network of the factory, and the equipment is interoperable and interchangeable. Automatic control equipment and systems are connected to the information network to provide more flexible system integration and data processing methods.

6. Intelligent manufacturing technology: apply information and communication technology to the manufacturing process, and apply industrial Internet technology in practice to realize the digitization and data sharing of system information. Practically apply technologies such as data encryption, firewall settings, and authority control to protect the security of production networks, office networks, and computer systems from unauthorized modification, destruction, or disclosure, and to meet emergency data processing needs. Select and apply sensor technology, automatic identification technology (RFID radio frequency identification, etc.), PLC technology, digital twin technology, MES and data processing, optimize the process and parameters of the production system, improve efficiency, reduce costs, obtain equipment operation parameters, monitor Equipment running status to realize predictive intelligent maintenance.

3. Practical Training That Can Be Completed

Students using this system can learn to master the following skills:

1) Sensor detection technology: including optical fiber sensors, photoelectric sensors, inductive sensors, etc. commonly used in industrial automation. On this device, students can get to know each sensor and master how to use each sensor.

2) Electrical control system: The drawings of the electrical part are designed according to industrial standards. Students can learn circuit principle analysis, PLC I/O address checking and equipment circuit analysis methods on this equipment.

3) Motor drive technology: including servo motors, stepper motors, AC motors and drivers, etc. Students can understand and master the use of each motor on this device.

4) Siemens PLC technology: students can practice PLC wiring, programming and debugging on this device.

5) Internet of Things technology: installation and testing of industrial Internet perception layer equipment, connection and configuration of Internet of Things network transport layer, deployment of industrial Internet application layer, joint debugging of industrial Internet collaborative manufacturing system.

6) Configuration technology: Students can practice programming of Siemens configuration software and communication between configuration software and PLC on this device.

7) System maintenance and fault detection technology: This part focuses on the content and methods of daily maintenance of mechatronic equipment, as well as common fault analysis and troubleshooting methods.

8) Digital twin technology: digital 3D model building and layout, virtual PLC debugging, virtual production line beat optimization, etc.

9) Industrial robot technology: use basic knowledge and skills in industrial automation control technology, robot automatic production line application, PLC and peripheral equipment application, etc., to carry out industrial robot assembly and testing, operation programming, installation and debugging in the field of industrial robot technology, industrial robot Sales and technical services, etc.

10) MES technology and application: the user places an order through the MES system, selects the demand information at the same time when placing the order (the demand information is provided in the form of multiple options, and the user can choose bookmarks of different colors), and the order information is issued to the manufacturing line through the MES system for production.

11) Logistics technology: not only transshipment, handling, assembly, warehousing technology, but also identification, data transmission and tracking technologies.

12) IT technology: mainly includes network planning, network wiring, firewall, VPN, gateway, router settings, etc.

13) Information security: The main two LANs are interconnected, the network firewall is configured, and the gateway provides filtering and security functions