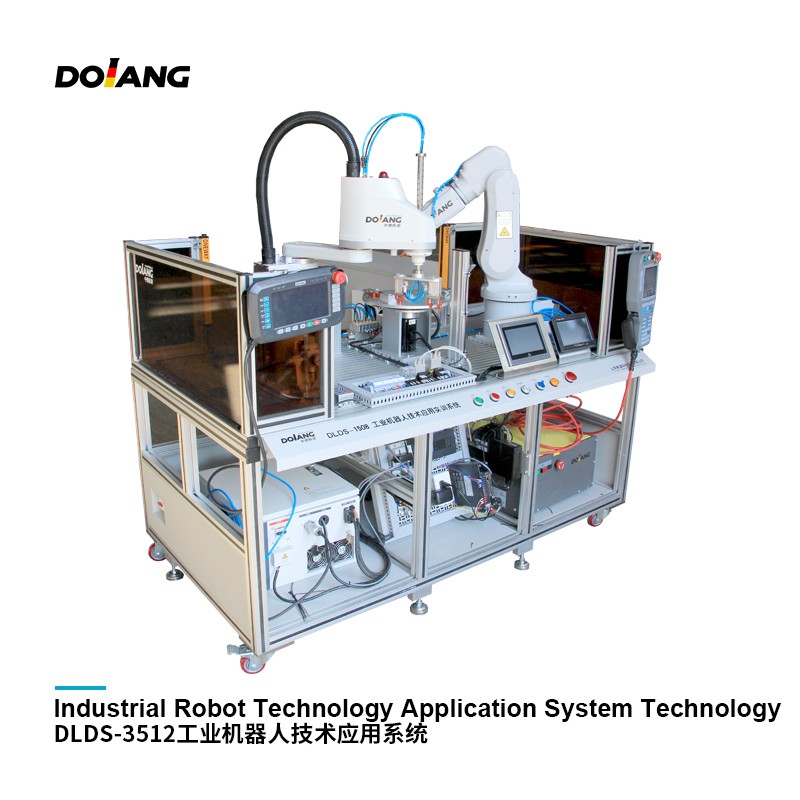

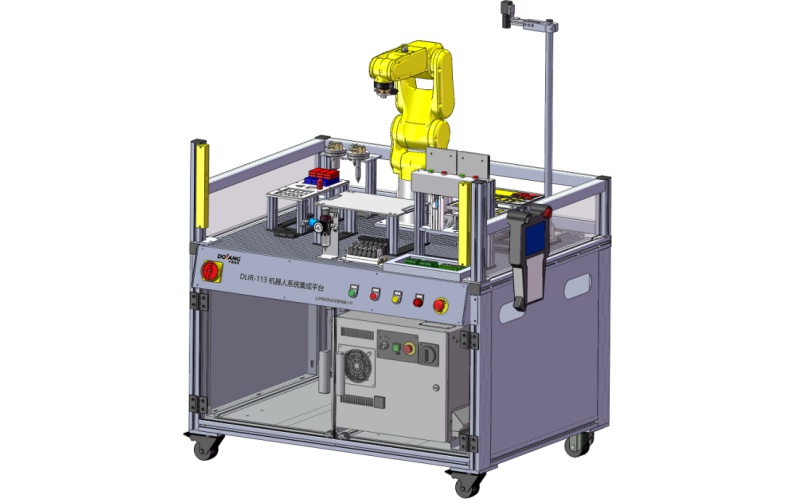

DLDS-1190 Industrial Robot Comprehensive Training System

The DLDS-1190 training system is equipped with FANUC industrial robot, SIEMENS PLC. It is equipped with the vision system (2D) of the FANUC intelligent camera, a unit of machining automation task, a basic operation assessment module, a gift packaging task unit, an intelligent transfer-sorting-palletizing task unit, a digital keyboard assembly task unit, a process application welding task unit, components, etc.

1. Overview

The DLDS-1190 training system is equipped with FANUC industrial robot, SIEMENS PLC. It is equipped with the vision system (2D) of the FANUC intelligent camera, a unit of machining automation task, a basic operation assessment module, a gift packaging task unit, an intelligent transfer-sorting-palletizing task unit, a digital keyboard assembly task unit, a process application welding task unit, components, etc.

With this TVET training equipment, students can learn about operating, debugging, PLC programming, PLC principle, visual application of industrial robots, sensor technology, Ethernet communication technology of Profinet industrial, etc.

2. Training Contents

1) Industrial robots installation

2) Industrial robotics teach pendant installation

3) End tools of industrial robots installation

4) Industrial robotics parameters setting

5) Industrial robot manual speed and operation mode practical training

6) Checking the industrial robots’ common information

7) The introduction to industrial robots programming instructions

8) The industrial robot programs backup and recovery

9) The industrial robot’s initial power-on and IO configuring

10) The calibration of the industrial robot coordinate system training

11) Setting of industrial robots’ safe working area

12) Error diagnosis of industrial robots and maintenance

13) Training in electrical drawings recognition and reading

14) Electrical connection and pneumatic circuit connection

15) The application of detection switches, sensors, pneumatic components

16) The installation and application of PLC and HMI

17) Communication between different parts: the PLC and the robot; the HMI and the PLC

18) Practical training in visual communication and industrial robots

19) Application of quick-change tool for industrial robotics

20) The industrial robot work tasks such as plane trace, space trace, and surface trace.

21) Robot training operating via robot simulation software