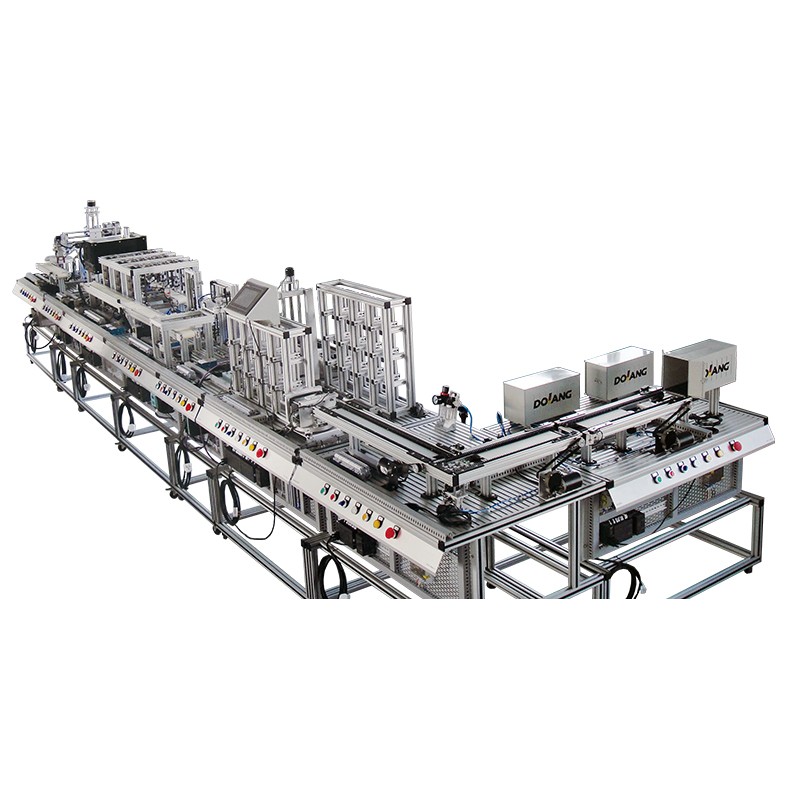

DLWL-800A Modular Modern Logistics Manufacture Process System

- Dolang

- China

- 30-60DAYS

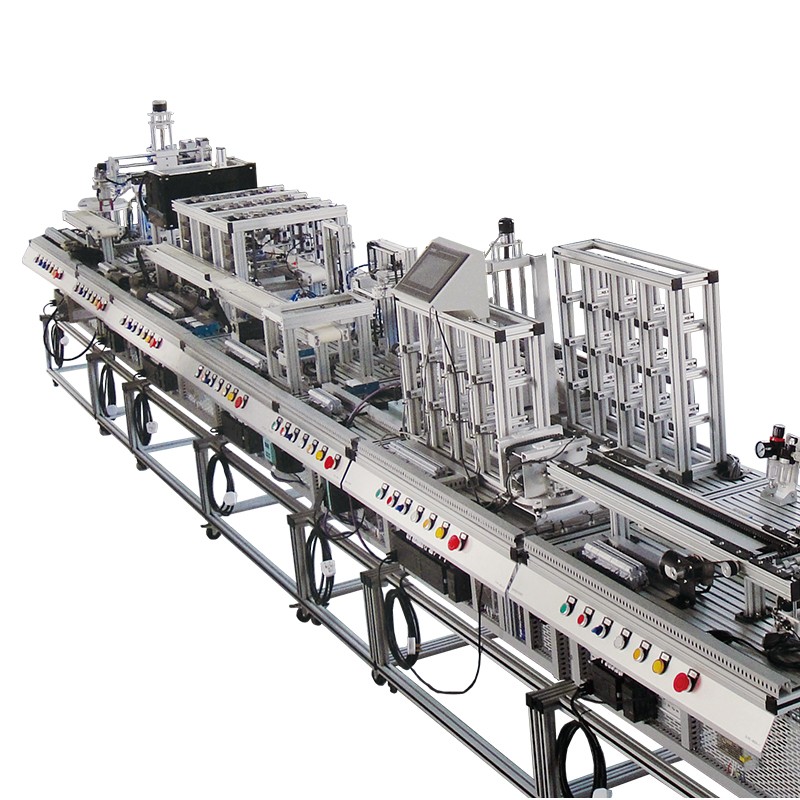

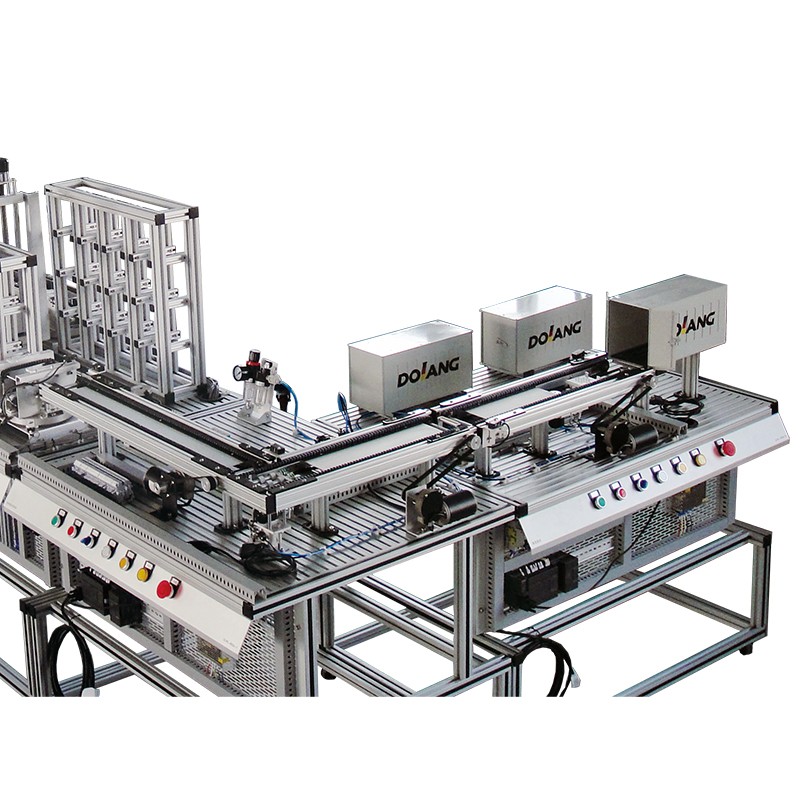

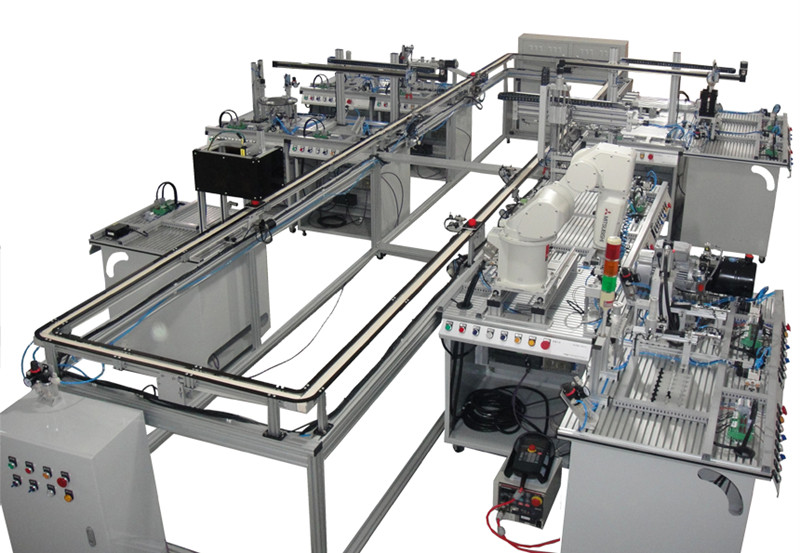

The system adopts a modular design of independent units, completes with electrical bus and mechanical bus, and finally connects between modules (stations). Each unit module (station) can work independently, and various system units can be connected in various ways. Process requirements, hung on the transmission line with the ring-shaped workpiece transmission system as the mechanical bus, and connected to a variety of different training models through the electrical bus; all the control signals and power signals of the controllers, sensors, and actuators are led to the interface The unit and interface have a specially designed misoperation protection circuit to ensure the safety of man and machine.

DLWL-800A Modular Modern Logistics Manufacture Process System

Equipment Overview

The system adopts a modular design of independent units, completes with electrical bus and mechanical bus, and finally connects between modules (stations). Each unit module (station) can work independently, and various system units can be connected in various ways. Process requirements, hung on the transmission line with the ring-shaped workpiece transmission system as the mechanical bus, and connected to a variety of different training models through the electrical bus; all the control signals and power signals of the controllers, sensors, and actuators are led to the interface The unit and interface have a specially designed misoperation protection circuit to ensure the safety of man and machine.

Technical Parameters

1. Input power: single-phase~220V±10% 50HZ

3. AC220V AC power supply

4. 24V DC power output

5. Emergency stop button for accident

6. Power failure protection

7. Working environment: temperature -10℃~+40℃ relative humidity 35%~65% (25℃) altitude<4000M

8. Device capacity: ≤5kVA

9. Operating compressed air: 5~6bar

10. Single table size: ①980x750x1500mm ②600x750x1500mm; table height: 750mm

Overall size: 6100x1730x1500mm

Training Content

1. Manipulator handling system unit

★Complete the inching control training of the cylinder;

★Complete the extension and retraction control training of the cylinder;

★Complete cargo box feeding training;

★Complete the training of material feeding;

★Complete the knowledge training of servo motor

★Complete the practical training of the working principle of the servo motor

★Complete the wiring training of the servo motor

★Complete the parameter setting training of the servo motor

★Complete the turntable servo positioning control training

★Complete the training of loading the cargo into the container

★Complete cargo container transportation training;

★Complete the pulse control training of stepper motor;

★Complete the X-axis control training of the manipulator;

★Complete the Y-axis control training of the manipulator;

★Complete the manipulator rotation axis control training;

★Complete the dual-axis linkage control training;

★Complete three-axis linkage control training;

★Complete the training of manipulator finger gripping material;

★Complete the training of manipulator air finger discharge;

★Complete the training of manipulator air finger rotation;

★Complete the encoder acquisition training;

★Complete encoder acquisition and control training;

★Complete the position control training of the servo motor;

★Complete stepper motor motion control training;

2. Visual inspection system unit

★Complete the practical training of the working principle of the visual recognition system;

★Complete the training of focusing;

★Complete the dimming training;

★Complete the training of sensor trigger signal;

★Complete the training of the capture process;

★Complete the training of debugging imaging principle with software;

★Complete the data processing training of PLC receiving visual signals;

★Complete the training on belt transportation of cargo containers;

★Complete PLC programming practice training;

3. Automatic cargo identification buffer system unit

★Complete the operation and stop training of the feeding belt;

★Complete the training of using color mark sensor;

★Complete cargo container inspection training;

★Complete the training of cargo container positioning detection;

★Complete cargo box entrance inspection training;

★Complete the warehousing training of qualified yellow workpieces;

★Complete the warehousing training of qualified green workpieces;

★Complete the storage training of unqualified workpieces;

★Complete the outbound training of qualified yellow workpieces;

★Complete the outbound training of qualified green workpieces;

★Complete the manual delivery training of unqualified workpieces;

★Complete the operation and stop training of the discharge belt;

5. Stacking system unit

★Complete the training of the control of the extension and retraction of the stopper cylinder;

★Complete the practical training of inverter working principle

★Complete the training of inverter speed regulation

★Complete the training of counting the number of imported cargo boxes;

★Complete the training of color classification and control of cargo boxes;

★Complete the training of cargo box A arrangement;

★Complete the training of cargo box B arrangement;

★Complete pallet feeding training;

★Complete pallet transportation training;

★Complete the training of cargo transportation to pallet

★Complete one layer of cargo boxes;

★Complete the second layer of stacking containers;

Six, automatic storage system unit

★Complete the rotation control training of the warehousing workpiece table;

★Complete the warehousing control training of the warehousing workpiece table

★Complete the outbound control training of the inbound workpiece table

★Complete the practical training on the control principle of the tunnel crane;

★Complete the training of stepper motor control;

★Complete the practical training on X-axis control of road crane;

★Complete the practical training of Y-axis control of road crane;

★Complete the training on Z-axis control of road crane;

★Complete the practical training of 2-axis linkage control of lane hoisting;

★Complete the training of the yellow cargo box storage operation;

★Complete the training of the storage operation of the green container;

★Complete the rotation control training of the outbound workpiece table;

★Complete the inbound control training of the outbound workpiece table

★Complete the outbound control training of the outbound workpiece table

★Complete the training of the yellow cargo box out of the warehouse;

★Complete the training of the outbound operation of the green container;

★Complete the training of compiling touch screen pictures;

★Complete the warehousing operation training of the yellow cargo box with the touch screen;

★Complete the operation training of yellow cargo box with touch screen;

★Complete the warehousing operation training of green cargo boxes with touch screen;

★Complete the operation training of the green cargo box with the touch screen;

★Complete the control training with button operation;

Seven, cargo flow control system unit

★Complete the training of motor start and stop sequence;

★Complete the training of chain operation and stop control;

★Complete the training of the lift control of the cylinder;

★Complete the training of pallet steering control;

8. Container system unit

★Complete the training of motor start and stop sequence;

★Complete the training of chain operation and stop control;

★Complete the training of the lift control of the cylinder;

★Complete the practical training of the control of the loading motor into the container

★Complete the training of controlling the loading motor out of the container

★Complete the training of the control of the loading motor in and out of the container

★Complete the training of container packing control;

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.