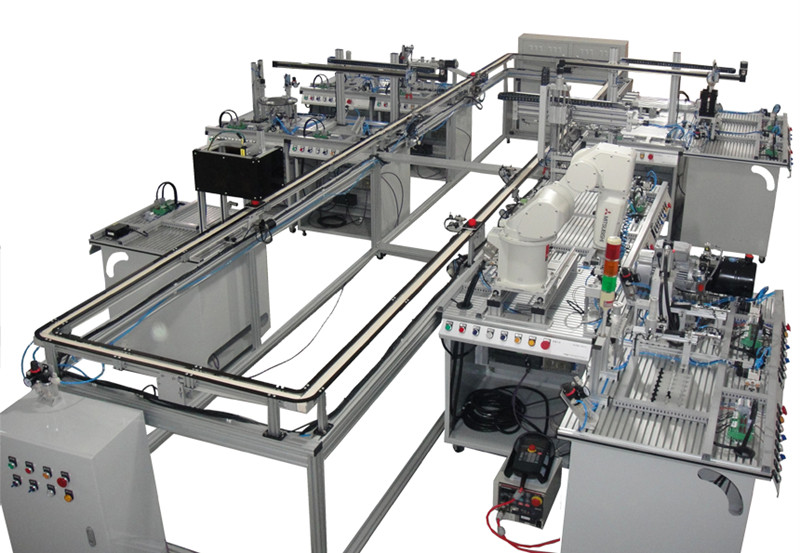

DLRB-1601 Didactic Industrial robot Vocational FMS Mechatronics Trainer Equipment

- Dolang

- China

- 30-60days

FMS training system can be used for PLC technical training,industrial robot training,sensor training, image detection technology training,pneumatic technology training,hydraulic technology training,electrical control system training, motor drive technology training and network training.

Modular Production System training equipment is an ideal skills training system for industry 4.0 technical personnel to learn and train skills.

DLRB-1601 Didactic Industrial robot Vocational FMS Mechatronics Trainer Equipment

Equipment Overview

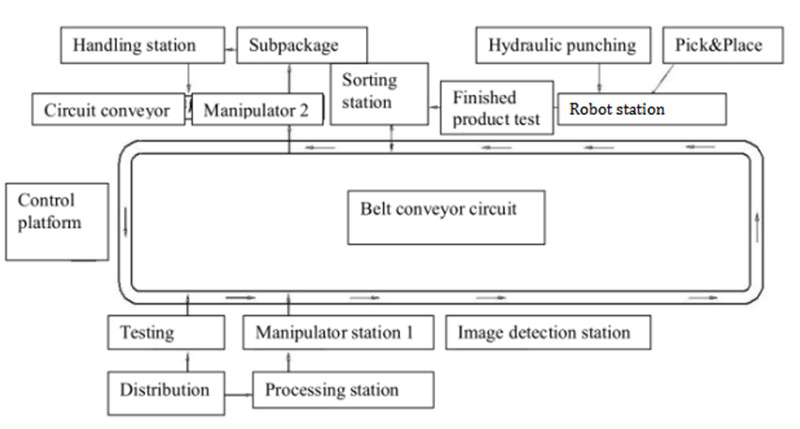

DLRB-1601 Didactic FMS Mechatronics Training Equipment: The complete FMS training system including 16 stations: control platform, distribution station,testing station, manipulator station 1, processing station, image detection station, Pick&Place station,Hydraulic punching station, robot station, Finished product test station, sorting station,manipulator station 2, subpackage station, handling station, storage station and circuit conveyor station.

Technical Parameters

1. Input power: Single phase 220V±10% 50Hz 2. Protection against leakage: I△n≤30mA, t≤0.1S 3. Power supply: AC220V 4. Output power:24V DC 5. Emergency stop button 6. Temperature: -10℃~+40℃; relative humidity: 35%~65%(25℃),Height<4000M 7. Capacity: ≤10kVA 8.Operating compressed air: 5~6bar 9. Dimension of each station: 750×750×1620mm, height:810mm; Total dimension: 8000x4250x1620mm |

Training Content

1. Control platform

1) Practice installation of TIA Siemens S7-1200 software installation training;

2) Complete the hardware configuration training of TIA Siemens S7-1200 software programming

3) Complete of TIA Siemens S7-1200 software programming training

4) Practice on the installation of PC configuration software;

5) Practice on the configuration software practical training;

6) Practice the configuration software configuration training of the host computer;

7) Practice the communication training of the host computer configuration software;

8) Complete the signal acquisition training for each slave station;

9) Complete the network address setting training;

2. Distribution station

1) Complete the magnetic sensor adjustment training

2) Complete the fiber optic sensor adjustment training

3) Complete the pressure detection adjustment training;

4) Complete cylinder speed governing training

5) Complete cylinder control training;

6) Complete the tilt cylinder control training;

7) Complete block automatic feeding training

3. Testing station

1) Complete magnetic sensor adjustment training

2) Complete material detection sensor (combination) adjustment training

3) Complete workpiece height detection sensor (combination) adjust training

4) Complete cylinder speed governing training

5) Complete cylinder control training

6) Complete motor speed control training

7) Complete red workpiece detection training

8) Complete black workpiece detection training

9) Complete metal workpiece detection training

10) Complete unqualified workpiece detection training

11) The workpiece automatically detect Training

4. Processing station

1) Complete magnetic sensor adjustment training

2) Complete photoelectric sensor adjustment training

3) Complete inductive sensor adjustment training

4) Completed cylinder speed governing training

5) Complete turntable control training;

6) Complete DC motor control training;

7) Complete processing control training;

8) Complete detection and control training

5. Manipulator station 1

1) Complete magnetic switch adjustment training

2) Complete fiber optic sensor adjustment training

3) Complete inductive sensor adjustment training

4) Completed cylinder speed governing training

5) Complete gas fingers to take raw materials control training;

6) Complete gas fingers to take qualified material control training;

7) Complete gas finger to take unqualified material control training;

8) Complete DC motor control training;

9) Complete workpiece automatic handling control training;

6. Image detection station

1) Complete photoelectric sensor adjustment training

2) Complete visual identity system work principle training;

3) Complete swap focal length training;

4) Complete dimming training;

5) Complete sensor trigger signal training;

6) Complete capture process training;

7) Complete software debugging imaging principle training;

8) Complete PLC receives visual signal data processing training;

7. Pick&Place station

1) Complete inductive sensor adjustment training

2) Complete cylinder speed governing training;

3) Complete cylinder control training;

4) Complete three-color light control training

8. Hydraulic punching station

1) Complete fiber optic sensor adjustment training

2) Complete magnetic sensor adjustment training

3) Complete cylinder speed governing training

4) Complete hydraulic principles training;

5) Complete hydraulic control training;

6) Complete cover feeding control training;

7) Complete cover extrusion control training;

8) Complete cover push-off control training;

9) Complete the AC motor control training;

10) Complete cover automatic feeding, extrusion control training;

9. Robot station

1) Complete magnetic sensor adjustment training

2) Complete fiber optic sensor adjustment training

3) Complete cylinder speed governing training

4) Complete robot principles training;

5) Complete robot programming software training;

6) Complete robot to take qualified materials block of training;

7) Complete robot to take unqualified materials block training;

8) Complete the robot put down qualified materials block training;

9) Complete robot put down unqualified materials block training;

10) Complete trobot to take the spring training;

11) Complete robot to take piston Training;

12) Completed robot to assemble workpiece training;

10. Finished product test station

1) Complete capacitive sensor adjustment training

2) Complete fiber optic sensor adjustment training

3) Complete inductive sensor adjustment training

4) Complete color detection control training

5) Complete DC motor control training;

6) Complete workpiece automatic detect control training;

11. Sorting station

1) Complete magnetic sensor adjustment training

2) Complete DC motor control training;

3) Complete X-axis control training;

4) Complete Y-axis control training;

5) Complete X, Y axis control training;

6) Complete Z-axis control training;

7) Complete sort the red workpiece control training;

8) Complete sort black workpiece control training;

9) Complete sort metal workpieces control training;

10) Complete pick up red workpiece control training;

11) Complete pick up black workpiece control training;

12) Complete pick up metal workpiece control training;

13) Complete workpiece automatically warehousing control training;

14) Complete workpiece automatically EX warehouse control training;

12. Manipulator station 2

1) Complete magnetic switch adjustment training

2) Complete fiber optic sensor adjustment training

3) Complete inductive sensor adjustment training

4) Complete cylinder speed governing training

5) Complete gas finger pick-up control training;

6) Complete the gas finger put-down control training;

7) Complete pulse output training;

8) Complete stepper motor control training;

9) Complete gas fingers pick-up workpiece control training (odd);

10) Complete gas fingers pick-up workpiece control training (even);

11) Complete workpiece automatically handling control training;

13. Subpackage station

1) Complete magnetic switch adjustment training

2) Complete of the fiber optic sensor adjustment training

3) Complete cylinder speed governing training

4) Complete pallet feeding training

5) Complete A, B position control training

6) Complete pallet automatically feeding training

14. Handling station

1) Complete magnetic sensor adjustment training

2) Complete cylinder speed governing training

3) Complete telescopic cylinder control training

4) Complete lift cylinder control training

5) Complete tilt cylinder control training

6) Complete pallet automatically handling training

15. Storage station

1) Complete magnetic sensor adjustment training

2) Complete the fiber optic sensor adjustment training

3) Complete the DC motor control training

4) Complete warehouse A storage training

5) Complete warehouse B storage training

6) Complete warehouse C storage training

7) Complete automatic storage control training

16. Circuit conveyor station

1) Complete magnetic sensor adjustment training

2) Complete photoelectric sensor adjustment training

3) Complete cylinder speed governing training

4) Complete cylinder control training

5) Completion DC motor control training

6) Complete connection with the detection unit training

7) Complete connection to manipulator 1 training

8) Complete connection to robot unit Training

9) Complete connection to automatic warehousing training

10) Complete connection to manipulator 2 training

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.