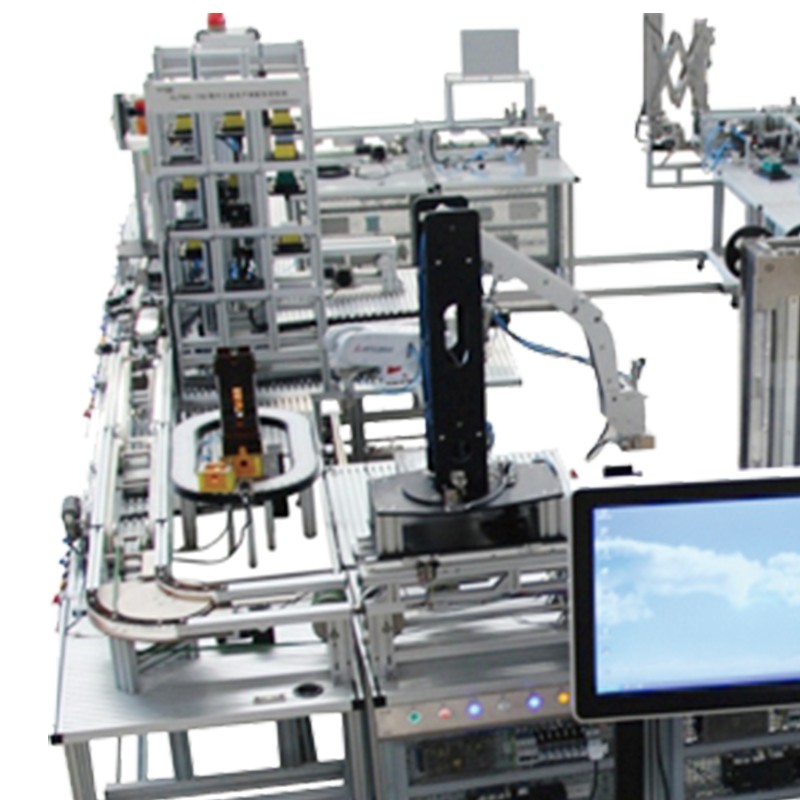

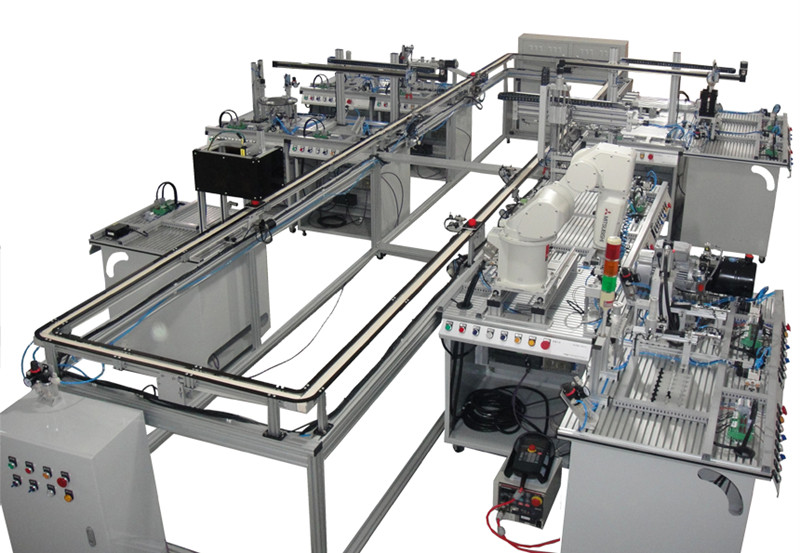

DLFMS-1700B Modern Industrial Production Assembly Training System

- Dolang

- China

- 30-60DAYS

The stations of the system are installed on aluminum profile panels, and the stations can be easily connected together to form an automatic processing line. The production line is controlled by a Siemens PLC system, and the stations are connected through Ethernet bus communication.

Highly integrated

Highly open

Modular

High scalability

Flexibility

DLFMS-1700B Modern Industrial Production Assembly Training System

Equipment Overview

DLFMS-1700B flexible manufacturing system is a flexible manufacturing system composed of Ethernet bus. It can complete the process of workpiece processing, inspection, transmission, transportation, storage, etc., which truly reproduces the actual industrial production process. Each station of the system is installed on a slotted aluminum substrate, and each station can be easily connected together to form an automatic flexible manufacturing production line. Each station can be self-contained, and can be connected with other stations to form a unity of the system. The modules are easy to build, disassemble and maintain, and the stations can be combined at will. The information exchange between stations transfers data through the Ethernet bus, and the current working status and data processing conditions of each station are summarized on the master control platform. The master control platform coordinates the corresponding actions of each station as needed, and finally makes each station very soft. Complete the commands issued by the system in a coordinated manner.

Technical Parameters

1. Input power: AC 220V±10% 50HZ

2. Leakage protection: I△n≤30mA, t≤0.1S

3. AC220V AC power supply

4. 24V DC power output

5. Emergency stop button, power indicator, power indicator

6. Working environment: temperature -10℃~+40℃ relative humidity<85%(25℃) altitude<4000M

7. Device capacity: <4KVA

Training Content

1. The design and application of PLC

(1) Data transmission function experiment

(2) Timing, counting and shifting function experiments

(3) Comparative function experiment

(4) Application experiment of stepping function

(5) Application experiment of jump function

(6) Application experiment of subroutine call function

(7) Application experiment of interrupt control function

(8) Application experiment of PWM control function of frequency conversion speed regulation

(9) Application experiment of stepping motor speed position control function

(10) Program design of detection system

(11) Program design of variable frequency speed regulation circular automatic transmission system

(12) Program design of automatic storage system

2. Sensor technology and application

(1) Research and application of characteristics of photoelectric sensor

(2) Research and application of characteristics of inductive sensors

(3) Research and application of characteristics of electromagnetic sensors

(4) Characteristic research and application of position sensor

3. Pneumatic control technology

(1) Working principle and application of electric control pneumatic valve

(2) Working principle and application of vacuum generator

(3) Working principle and application of pneumatic two-piece

(4) Working principle and application of various cylinders

4. Motion control system

(1) Control technology of servo motor positioning

(2) DC motor control technology

(3) Frequency conversion speed regulation technology of AC motor

5. Robot application technology

(1) Robot language action instruction programming

(2) Robot external IO control

(3) Application of handling robot

6. Vision sensor system

(1) The composition and application of machine vision

(2) Image collection and judgment

7. Hydraulic control system

(1) Composition and application of hydraulic pump station

(2) Installation of transmitter and signal acquisition

(3) Citation of the cylinder and construction of the circuit

(4) Application and control of solenoid valve

(5) Proportional control of hydraulic circuit

(6) Application of HMI man-machine interface

(7) Transmission principle of sprocket chain and connecting rod mechanism

8. Radio frequency identification system

(1) Application of radio frequency technology;

(2) Reading and writing of code body data;

9. Configuration monitoring and man-machine interface technology

(1) Basic application of configuration monitoring software

(2) Configuration monitoring software communication application experiment

10. Mechanical structure training technology

(1) Research on the design and characteristics of belt drive mechanism

(2) Research on the design and characteristics of gear transmission mechanism

(3) Design and characteristic research of cylindrical guide rod

(4) Research and application of the characteristics of ball screw

(5) Design and characteristic research of toothed belt

11. Fault detection technical skills training

(1) Elimination training of program fault settings

(2) Trouble shooting training for parameter fault setting

(3) Troubleshooting training for electrical wiring fault settings

(4) Elimination training of mechanical fault settings

12. Network communication technology and fieldbus technology

(1) Principles and applications of network communication

(2) Research and application of fieldbus module

(3) Research and application of fieldbus communication protocol

(4) Communication research between the fieldbus master station and slave station

13. Experiments on various sensors and encoders

(1) Positioning detection technology training of photoelectric sensor

(2) Technical training of limit detection of photoelectric sensor

(3) Technical training on limit detection of travel switch

(4) Positioning detection technology training of travel switch

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.