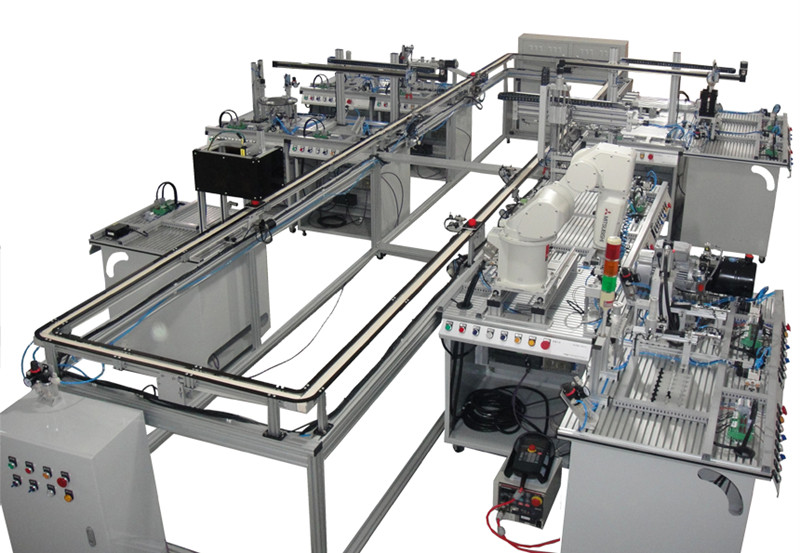

DLFMS-8000 Flexible Manufacturing System

- Dolang

- China

- 30-60DAYS

The system covers the mechanical, electrical, optical and pneumatic technology which involved in multi-disciplinary knowledge. Minimize the gap between the training process and the actual production process.The technologies involved including: PLC control, sensor detects, pneumatic, motor drive, servo drive, stepper drive, computer configuration control and man-machine interface, mechanical structures and systems installation and commissioning, fault detection skills, PROFIBUS, visual inspection and image processing,frequency control, touch screen, motion control, process control, computer technology and systems engineering.

DLFMS-8000 Flexible Manufacturing System

Equipment Overview

The system covers the mechanical, electrical, optical and pneumatic technology which involved in multi-disciplinary knowledge. Minimize the gap between the training process and the actual production process.The technologies involved including: PLC control, sensor detects, pneumatic, motor drive, servo drive, stepper drive, computer configuration control and man-machine interface, mechanical structures and systems installation and commissioning, fault detection skills, PROFIBUS, visual inspection and image processing,frequency control, touch screen, motion control, process control, computer technology and systems engineering.

Technical Parameters

1) Input power supply: single-phase ~ 220V ± 10% 50Hz/60Hz

2) Leakage protection: I △ n ≤ 30mA, t ≤ 0.1S

3) AC220V power supply

4) 24 V DC power output

5) Emergency stop button, power indicator

6) power and inadvertent energization protection

7) Working environment: Temperature -10 ° C ~ +40 ° C Relative humidity 35% to 65% (25 ° C) Altitude <4000M

8) Installed capacity: ≤ 5kVA

9) Operation of compressed air: 5 to 6bar

10) Size of each station: ① 600x750x1450mm ② 1200x750x1400mm; Table height: 750mm

Overall dimensions: 4100x2400x1450mm

Training Content

1. Control platform

1) Complete the training of the PROFIBUS-DP network;

2) Complete signal acquisition of slave station training;

3) Practice Step V5.4 Siemens 300 software installation training;

4) Practice network information processing technology in the industry training;

5) Complete network address set training

2.Manipulator station

1) Complete stepper motor precision positioning control training;

2) Complete rotation axis control training;

3) Complete Y axis control training;

4) Complete X-axis control training;

5) Complete Z axis control training;

6) Complete dual-axis linkage control training;

7) Complete three-axis motion control training;

8) Complete four-axis motion control training;

9) Complete manipulator grapping action training;

10) sensor signal acquisition training;

3.Milling machine processing station

1) Complete converter parameter adjustment training;

2) Complete spindle frequency control forward and reverse training;

3) Complete Z-axis every position point action training;

4) Complete Z-axis back to reference point action training;

5) Complete X-axis every position point action training;

6) Complete X-axis back to reference point action training;

7) Complete Y-axis every position point action training;

8) Complete Y-axis back to reference point action training;

9) Complete XY dual-axis linkage control training;

10) Complete XYZ axis control linkage training;

11) Complete on knife control training;

12) Complete table workpiece clamping training;

13) Complete servo parameter setting training;

14) Complete external position control of servo drive control servo motor training;

15) Complete stepper motor control XY axis motor sports training;

16) Stepper motor control training;

17) Servo motor control training;

4.Visual inspection station

1) Complete training of visual recognition system work principle;

2) Complete swap the focus length training;

3) Complete sensor trigger signal training;

4) Complete training of the capture process;

5) Complete training of debugging imaging principle with software;

6) Complete data processing training of visual signal received by PLC;

7) Complete of the PLC programming exercise training

5. Heat-treatment station

1) Complete heat treatment process control training

2) Complete PLC programming training;

3) Complete analog control training;

4) Complete signal acquisition of PT100 training;

5) Complete chain transfer training;

6) Complete training on the handling agencies

7) Mechanical principles training;

6.Auto sorting station

1) Complete knowledge on cross institutions training;

2) Complete two-axis motion control training;

3) Complete gas finger movements principle training;

4) Complete sorting training on different parts;

5) Complete programming training on each part of executing agencies;

6) Complete regulation of throttle valve of the pneumatic circuit training;

7) Complete of training from the local to the whole;

7.ASRS station

1) Complete take pallets training;

2) Complete discharge pallet training ;

3) Complete micro switch adjustment training;

4) Complete lane crane control principle training;

5) Complete control principle of handling institutions training ;

6) Complete stepper motor positioning training;

7) Complete touch screen encoder training;

8) Complete take pallet training controlled by touch screen ;

9) Complete discharge pallet training controlled by touch screen ;

10) Complete push-button control training;

8.Auto transfer station

1) Complete motor sequence start and stop training;

2) Complete backgauge cylinder telescopic stop and discharge training;

3) Complete converter regulator training;

4) Complete motor and cylinder work with the stop and discharge training;

5) Complete sensor detects the motor running stop scalable training;

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.