DLRB-VS401 Robot Vision Training System

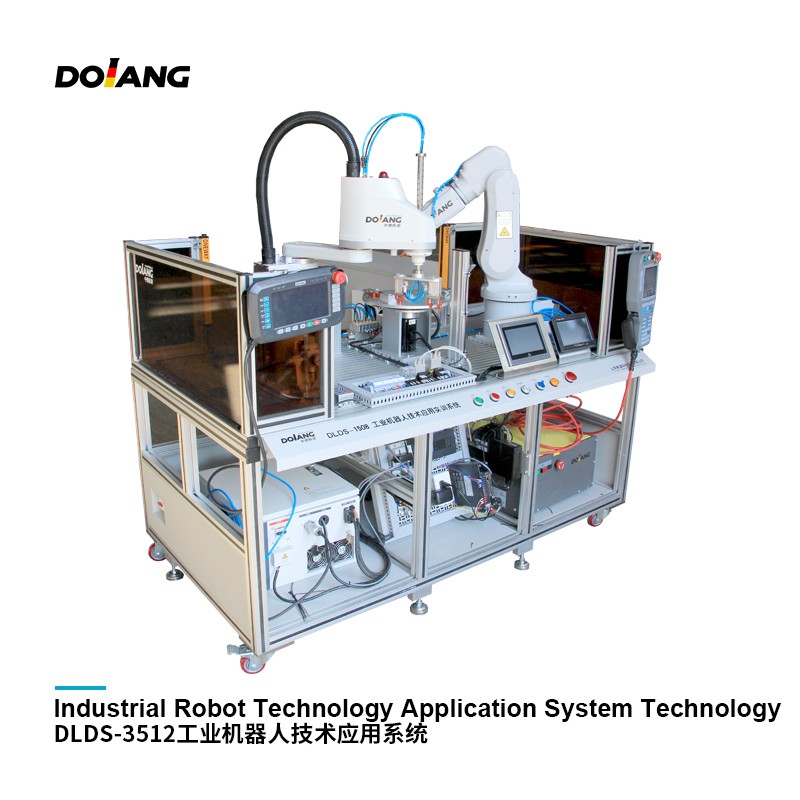

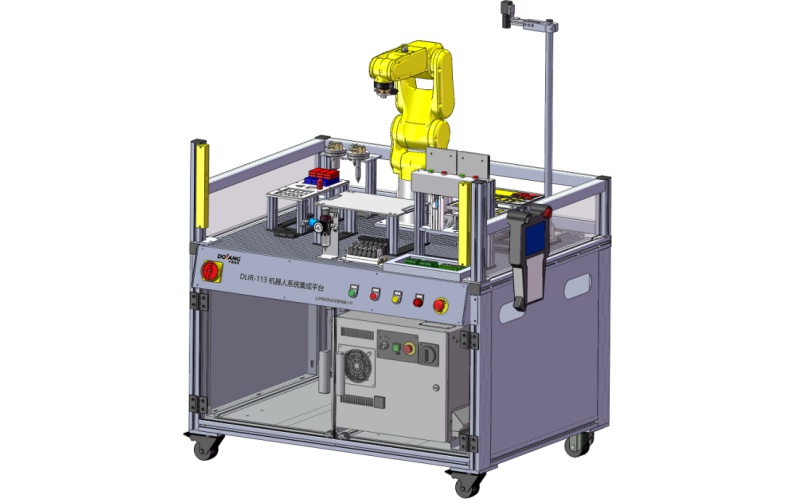

DLRB-VS401 robot vision training system is a comprehensive robot vision training platform developed by our company that integrates teaching, research, and learning. The overall equipment is composed of an aluminum alloy training platform, a six-axis robot, a vision system, a PLC controller, electrical and pneumatic devices, and other components. Modules can be flexibly combined, installed, and debugged according to training needs.

1.Specs

Model: DLRB-VS401 Robot Vision System

Power and voltage:AC power supply: single-phase AC220V±10% 50Hz; with automatic voltage regulator

Dimensions: length × width × height 1700mm × 900mm × 1550mm

Safety measures: Safety protection complies with relevant national standards.

2. Technical Function

All components of robot vision training system are installed on the profile table, and the mechanical structure, electrical control circuit, and actuator are relatively independent and are designed with industrial standard parts.

Through this robot vision training platform, you can carry out various training such as mechanical assembly, electrical circuit design and wiring, PLC programming, and debugging, intelligent visual process editing, industrial robot programming, and debugging applications, etc.

DLRB-VS401 suitable for the practical teaching of courses such as “Industrial Robot and Control Technology”, “Automation Technology”, “Machine Vision”, “Industrial Network Integration” and other courses related to automation in vocational colleges and technical schools.

3. Equipment Components

3.1 Six axis industrial robot

Choose Efort robot ER3-600. (Other robots are also available according to your needs)

3.2 Basic Platform

The basic platform is about 1700×990×1100mm, and the frame is built with 40mm aluminum profile structure; the installation panel is made of high-quality aluminum alloy panels with a thickness of 30mm and an interval of 25mm, and the robots or other actuators or modules can be installed arbitrarily. The bottom is a sheet metal structure, where robot controllers, functional modules, or accessories can be placed;

3.3 robotic grippers

The pneumatic gripper includes parallel finger cylinders, connecting flanges, etc., and is fixed on the end flange of the robot. It can be used for grasping materials and visual calibration pins for operations such as handling and tool coordinate system calibration.

3.4 Vision system

3.4.1 Visual inspection module

Composition: industrial camera, lens, adjustable bracket, parallel light source and digital controller, vision controller, vision software, etc.

Function: Detect the logistics, position, color, etc. on the conveyor belt, and cooperate with PLC to complete the sorting of materials.

3.4.2 Vision software

VisionMaster main interface

3.5 visual production line task module group

It includes a feeding module, a conveying module, and a storage module, which can realize operations such as sorting, testing, handling, and storage of the transferred workpieces. Detection can be realized by sensors or vision cameras

3.6 Electric control system

The electrical control system consists of input power supply, output power supply, terminal blocks, control panel, PLC, etc., and is mainly installed on the mesh plate at the bottom of the basic platform. The operation panel is installed at the front of the basic platform, which not only fits the industrial site, but is also convenient for candidates to operate.

3.7 Pneumatic system

Including air compressor, pressure regulating filter, reversing valve, and air pipe connector.

3.8 Supporting tools

Including hex wrench set, slotted screwdriver, Phillips screwdriver, etc.

4. Training Contents

1: Mechanical cognition training of robot training model

2: Pneumatic connection training of the motion control training model

3: Sensor training of the motion control training model

4: Circuit connection training of the motion control training model

5: Motion Control PLC Training

6: Robot Programming Training

7: Vision system detection programming training

8: Robot and PLC communication training

9: Robot and visual communication training

10: Comprehensive training of robots, PLC, and vision