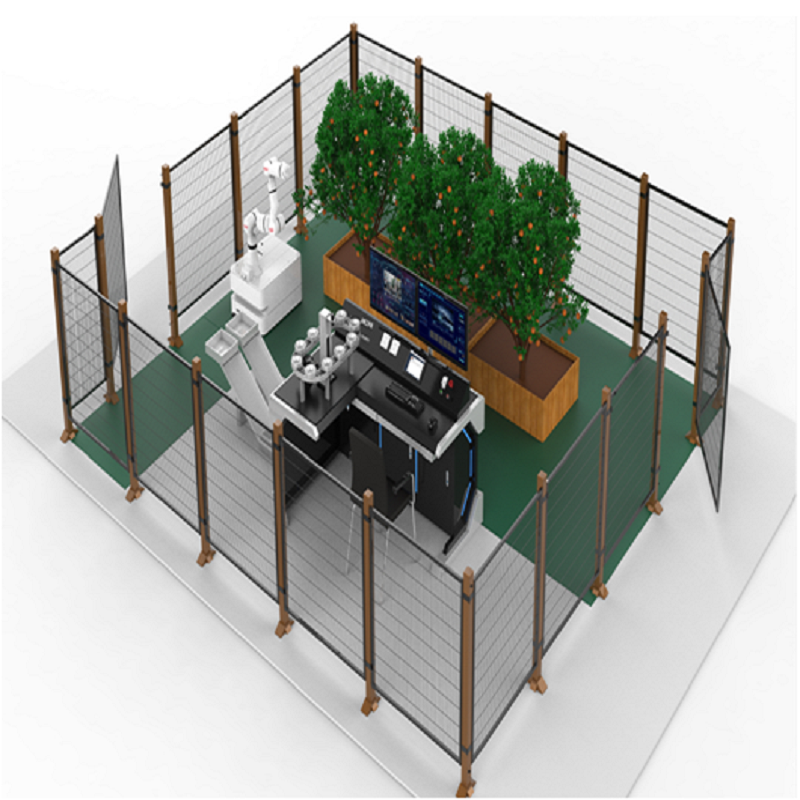

DLIM-512MS Industry 4.0 Technology Training Equipment

- DOLANG

- CHINA

- 40-60DAYS

1. DLIM-512MS Industry 4.0 Technology Training Equipment may build intelligent manufacturing cell production systems, install, debug, maintain, and maintain the mechanical parts, electrical systems, PLC control systems and sensors of key equipment such as CNC machine tools and industrial robots, suits for engineer technical training of industry 4.0 major.

2. It may operate and apply intelligent manufacturing units for product digital design, robot programming and operation, CNC machine tool programming and process optimization, part processing and online inspection, product assembly and quality control, etc.

1. Overview

DLIM-512MS Industry 4.0 Technology Training Equipment is a technical training equipment, which is composed of CNC lathe, CNC machining center, online detection unit, six axis industrial robot, industrial robot ground rail, automatic three-dimensional warehouse, central control system, MES system management software and electronic screen, etc.

2. Technical Parameter

2.1 Input power supply:

1)Power supply of CNC machining center: three phase four wire system, 3PH, AC380±5%, 50Hz,12KVA,MAX25A;

2)CNC lathe power supply: three phase four wire system, 3PH,AC380±5, 50Hz, 15KVA,MAX25A;

3)Power supply of industrial robot: three phase four wire system, 3PH,AC380±5%, 50/60Hz, 3.5KVA;

4)Control system power supply: single phase three wire system, AC220V±10%, 50Hz,3KVA.

2.2 Working environment:

1) The temperature is - 10 ℃ - + 40 ℃;

2) The relative humidity was less than 85% (25 ℃), and there was no water condensation;

3) Altitude < 4000m;

2.3 Output power supply:

DC regulated power supply: at least 24V/5A

2.4 Equipment size

About 8000×4800×2700mm(L×W×H)

2.5 Safety protection function:

Emergency stop knob, warehouse emergency stop knob, warehouse electromagnetic lock, safety door, etc.

3. Training Projects

1) Installation and application of PLC programming software

2) Press and application of HMI touch screen programming software

3) Installation and application of CAM programming software

4) Application of pneumatic technology

5) Application of sensor detection technology

6) Industrial robot installation, debugging, programming and application;

7) Industrial robot fixture installation, debugging, programming and application;

8) Off line simulation of industrial robot

9) CNC lathe's adjustment, maintenance and programming application;

10) The application of assembling, repairing and programming of NC Machining Center

11) Adjustment and application of on-line measurement of CNC machine tools;

12) Application of bus communication technology

13) Application of industrial automation network;

14) Application of motor drive technology

15) The application of motion control system;

16) The application of intelligent simulation technology;

17) The application of MES system;

18) Use of instruments and meters;

19) Safe and civilized production, etc.

4. FAQ

Q1. What kind of price terms we can choose ?

Dolang provide EXW, FOB, CIF, CFR and other price terms based on communication.

Q2. What is the payment terms ?

TT or LC at sight, all payments are released before delivery.

Q3. What is the lead time?

Dolang provide a 50days lead time for clients, if you have special demands, pls communicate with project manager.

Q4. Whats the after sales service contents?

Dolang provide 24 hours online support for user, it is free within 1st year,

if there is no spares changes demands.