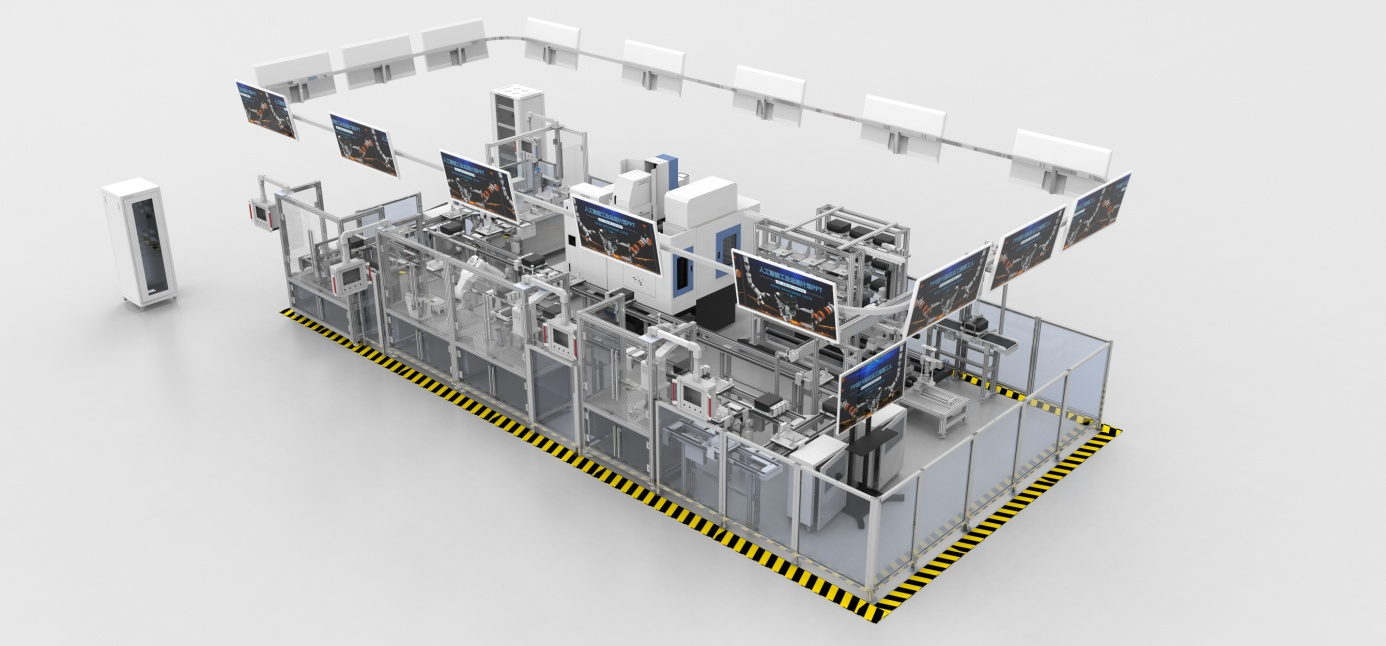

DLJS-X1806 Smart Manufacturing (photo frame) Automated Production Line System of vocational education equipment

- Dolang

- China

- 30-60DAYS

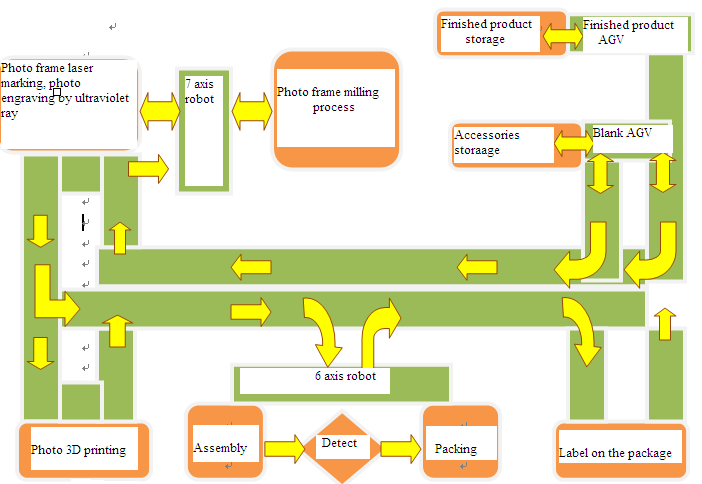

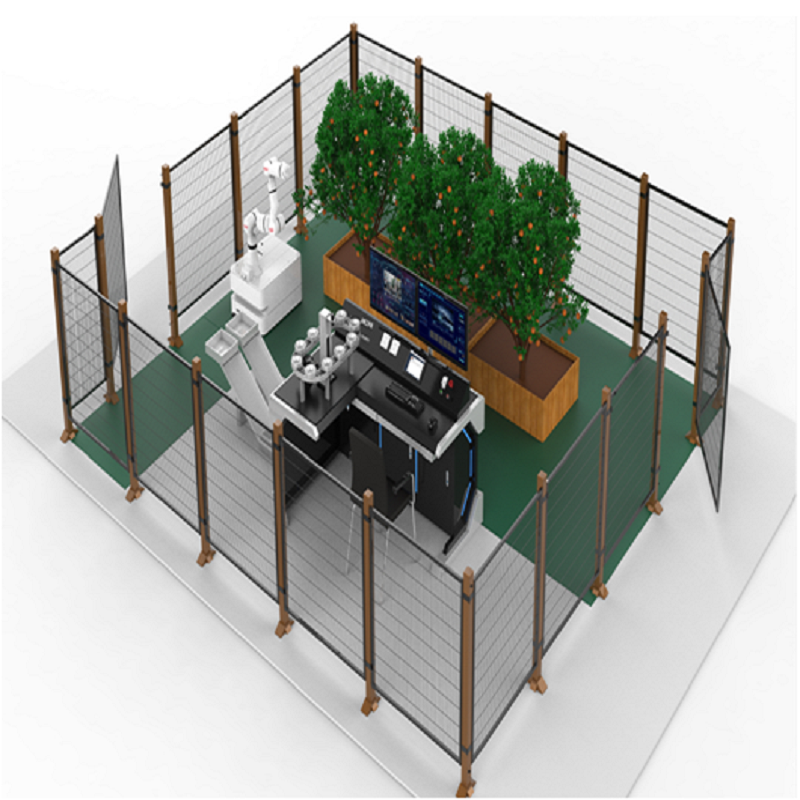

1) The equipment is complete, which can be applied to the production, application and training of different processes such as storage, machining, marking, 3D printing, assembly testing, packaging and transshipment of three kinds of photo frames.

2) The process unit has a clear distribution and modular design, which is convenient for observation, debugging and teaching guidance in the production process.

3) Flexible connection between processes, which can adapt to the simultaneous production of various products and the adjustment and switching between product processes.

4) Fully automatic control, automatic production and demonstration according to the set parameters.

5) MES intelligent management, which can comprehensively manage the materials, finished products, production, equipment, personnel, orders, etc.

6) practical production design, can be applied to the actual production of photo frames.

7) Factory layout, high security, humanized control station to ensure full monitoring of equipment movements.

DLJS-X1806 Smart Manufacturing (photo frame) Automated Production Line System

Equipment Overview

1) The overall production training system covers an area of 70 square meters. Length 11.1 m and width is 6.25m

2) Leave 2m pedestrian passage outside the fence.

3) Reserve 2 teaching entrance & exit port.

4) The safety fence is set on the protective fence. When the robot senses someone or some object passing through the working area, the entire production line will stop, and the alarm or notification will be notified and the video will be recorded.

The photo frame processing and assembly flexible automatic production training system is composed of auto-stereo warehouse, loading manipulator, distributing manipulator, automatic transmission line, 7-axis handling robot, CNC processing unit, marking unit, 3D printing unit, assembly & detecting unit, Packing unit, process monitoring display system, MES billboard, short-distance projector, feeding cabinet, PLC console, electric control cabinet, power distribution cabinet, etc.

Technical Parameters

1) Covering an area of 115.44 square meters (including channels), 15m × 8m.

2) Input power: three-phase four-wire system AC380V±10% 50HZ, single-phase 220V±10% 50H.

3) Working environment: temperature -10 °C - +40 °C, relative humidity <85% (25 °C), anhydrous beads condensation elevation <4000m.

4) Power control: automatic air switch on and off power supply, with over voltage protection, under voltage protection, over current protection, leakage protection system.

5) Air source, 3-7bar, 670L/min.

Training Content

Communication between the PLC and the remote I/O module;

Modbus-Tcp communicates between PLC and four-axis industrial robot;

TCP/IP communication between PLC and six-axis industrial robot;

Modbus-rtu communicates between PLC and the servo drive;

Profinet communication between PLC and RFID;

Profinet communication between PLC and PLC;

Communication between MES and PLC;

Industrial robot installation, debugging and programming;

HMI embedded touch screen application;

Application of bus communication technology;

Industrial automation network applications;

The application of PLC program control technology;

Industrial electrical control technology and applications;

Application of motor drive technology;

Principle and application of servo control system;

Application of motion control systems;

Machining technology and CNC machine programming;

Pneumatic deburring, grinding principle and application;

Principle and application of UV marking;

Laser marking principle and application;

Principle and application of automatic labeling machine;

3D printing principle and application;

AGV trolley control system application;

Application of product assembly technology;

Principle and application of visual inspection system;

Pneumatic execution and control technology;

Fixture tooling design and application;

Flexible intelligent manufacturing system design;

Application of industrial engineering technology;

Instrumentation use;

The application of MES production management system in intelligent manufacturing;

The application of video surveillance systems in industrial production;

Industrial production safety protection technology and civilized production.

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.