Purified water production line engineer training system

- DOLANG

- CHINA

- 40-60DAYS

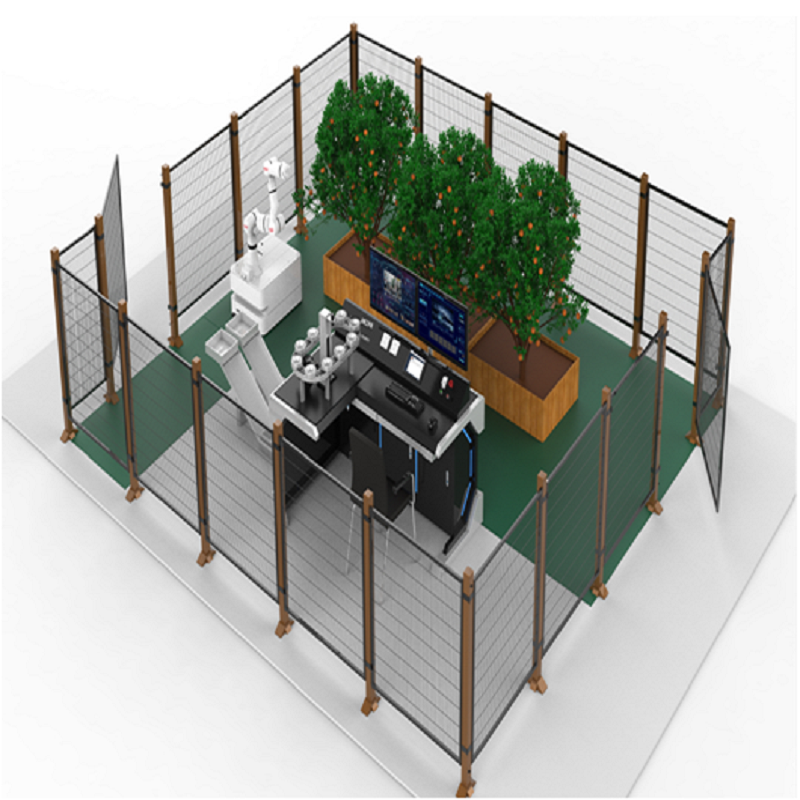

DLIM-201 Purified Water Production Line Training System belong to industrial automation production line, the engineer teaching equipment composed of these three sets of training devices can comprehensively reflect the control technology, installation technology, pneumatic technology and sensor technology used in the industrial field automation production process. The three parts of this production line can complete the work of pure water production, filling, handling, palletizing, storage, etc., completely simulating the working process of an industrial pure water production line.

1. Overview

DLIM-201 Purified Water Production Line Training System is a technical teaching equipment, which integrates teaching, training, demonstration, and real production functions, and consists of a filling production and process control device, a logistics palletizing training device, and a three-dimensional storage training device. The industrial automation production line composed of these three sets of training devices can comprehensively reflect the control technology, installation technology, pneumatic technology and sensor technology used in the industrial field automation production process. The three parts of this production line can complete the work of pure water production, filling, handling, palletizing, storage, etc., completely simulating the working process of an industrial pure water production line.

2. Technical Parameter

Filling Production And Process Control Device:

1. Input Power: single-phase three-wire (220V±10% 50Hz)

2. Working Environment: temperature -10℃~+40℃, relative temperature <85% (25℃) altitude <4000m

3. Device Capacity: <2KVA

4. Environmental Conditions:

Working Environment Temperature: -10℃~+45℃;

Maximum Monthly Average Relative Humidity: ≤90%;

Maximum Daily Average Relative Humidity: ≤95%;

Altitude: no more than 2000 meters;

Working Environment Conditions: There is no conductive particulate dust, no chemicals that corrode metals and damage insulation. The place of use should be protected from rain, snow, wind, and sand. The surrounding area should not be filled with water vapor or serious mold.

Logistics Palletizing Training Device:

1. Input Power: AC220V±10% 50Hz, Operating Power: DC24V

2. Ambient Temperature: -10℃~40℃, Ambient Humidity: ≤90% (25℃)

3. Machine Capacity: ≤10KVA

Three-Dimensional Storage Training Device

1. Input Power: AC380V±10% 50Hz, Operating Power: DC24V

2. Ambient Temperature: -10℃~40℃, Ambient Humidity: ≤90% (25℃)

3. Machine Capacity: ≤10KVA

3. Experimental Projects

Filling Production And Process Control Device:

1. Understanding of PLC hardware, programming and debugging of PLC switch quantity, analog quantity, pulse control program and network communication;

2. Understanding, installation and application of various water treatment equipment;

3. Application of electric drive;

4. Understanding, installation, wiring, debugging and application of various sensors;

5. Recognition of industrial control network, wiring, writing and debugging of networking programs;

6. Understanding of process control system, programming and debugging application;

7. Process operation and monitoring system management;

10. Selection, deployment and control of process joints, pipeline design and installation process, etc.;

Logistics Palletizing Training Device:

1. Programming operation of palletizing robot

2. Position control test of palletizing robot

3. Accuracy adjustment of palletizing robot

4. Offline simulation of palletizing robot

5. Offline programming of palletizing robot

6. Cargo transmission speed regulation operation

7. Programming and operation of cargo transfer process

Three-Dimensional Storage Training Device

1. Programming operation of handling robot

2. Position control test of handling robot

3. Accuracy adjustment of handling robot

4. Offline simulation of handling robot

5. Offline programming of handling robot

6. Roadway robot programming operation

7. Position control test of roadway robot

8. Accuracy adjustment of roadway robot

9. Offline simulation of roadway robot

10. Offline programming of roadway robots

11. Programming and operation of cargo handling process

12. Programming and operation of cargo warehousing process

13. Programming and operation of logistics warehousing system

4. FAQ

Q1. What kind of price terms we can choose ?

Dolang provide EXW, FOB, CIF, CFR and other price terms based on communication.

Q2. What is the payment terms ?

TT or LC at sight, all payments are released before delivery.

Q3. What is the lead time?

Dolang provide a 50days lead time for clients, if you have special demands, pls communicate with project manager.

Q4. Whats the after sales service contents?

Dolang provide 24 hours online support for user, it is free within 1st year,

if there is no spares changes demands.