DLYY-GZFX01 Hydraulic Fault Analysis Training System of vocational education equipment

- Dolang

- China

- 30-60DAYS

This device takes the injection molding machine hydraulic system commonly used in typical industrial sites as the training object, and trains students to be familiar with and understand the working principles and basic concepts of hydraulic transmission, the composition characteristics and applications of components, and the composition of the injection molding machine hydraulic system.

DLYY-GZFX01 Hydraulic Fault Analysis Training System of vocational education equipment

Equipment Overview

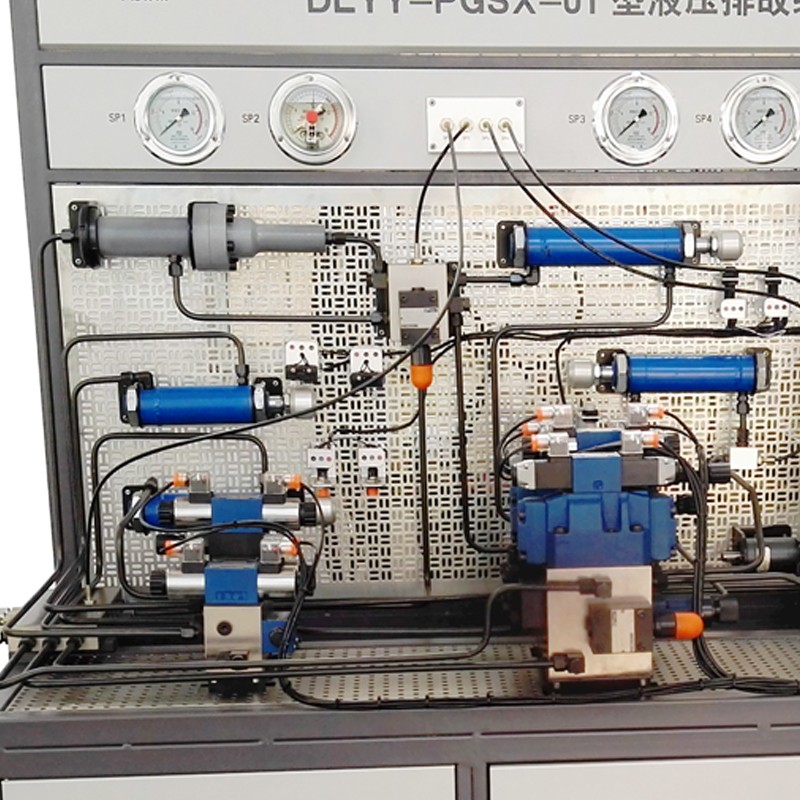

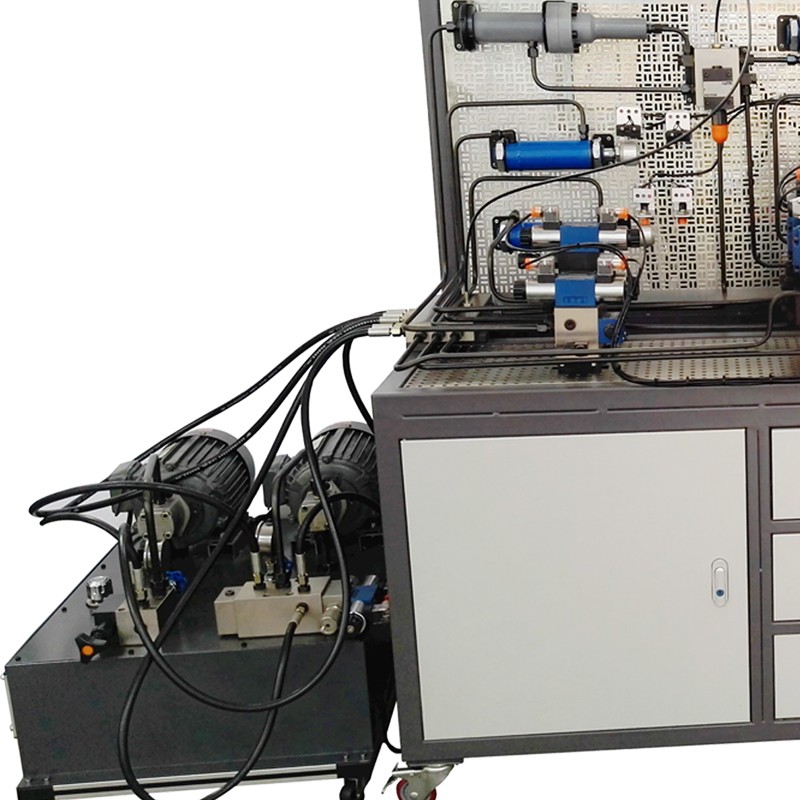

This DLYY-GZFX01 Hydraulic Fault Analysis Training System of vocational education equipment takes the injection molding machine hydraulic system commonly used in typical industrial sites as the training object, and trains students to be familiar with and understand the working principles and basic concepts of Hydraulic Fault Analysis ,hydraulic transmission, the composition characteristics and applications of components, and the composition of the injection molding machine hydraulic system. Preliminary mastery of hydraulic system debugging, handling and troubleshooting of common hydraulic system faults. At the same time, the device is also equipped with an intelligent man-machine operation assessment system. The teacher can set up the fault through the host computer or the intelligent man-machine operating system. The students analyze the fault phenomenon and the specific circuit, and finally perform the fault through the intelligent man-machine exchange system Elimination to improve the comprehensive ability of students. It is suitable for the practical training and teaching of "hydraulic transmission", "hydraulic and pneumatic transmission" courses of electromechanical majors in various vocational colleges.

Technical Parameters

(1) Power supply: three-phase four-wire~380±10% 50Hz

(2) System rated pressure 7Mpa, rated flow 16L/min

(3) Double motors: rated power 1.5kW, speed 1420r/min, insulation B

(4) Fuel tank: size 650 (length) X600 (width) X200 (height);

(5) Experimental table size: 1900 (length) × 720 (width) × 1800 (height)

(6) The size of the mesh work board on the vertical surface of the console: 1200 (length) * 660 (width) * 33 (height)

(7) The middle of the platform is equipped with an oil leakage pan and an oil collecting pan. Size: 1200 (length) * 620 (width) * 33 (height)

Training Content

1. Theoretical part

(1) Basic knowledge of hydraulic system failure;

(2) Failure classification of hydraulic system;

(3) Failure modes of hydraulic components and systems;

(4) Basic content of hydraulic fault diagnosis;

(5) The method of hydraulic fault diagnosis;

(6) Prevention of hydraulic system failure;

(7) Introduction to electrical control principles;

(8) Automatic detection and sensor technology;

(9) PLC control technology.

2. Practice part

(1) Diagnosis and troubleshooting methods of hydraulic pump failure;

(2) Diagnosis and troubleshooting methods of hydraulic component mismatch failure;

(3) Causes and elimination of hydraulic noise;

(4) Diagnosis and elimination methods of pressure valve failure;

(5) Diagnosis and elimination method of reversing valve failure;

(6) Evaluation and elimination methods of system design failures;

(7) Diagnosis and elimination methods of hydraulic pressure holding failure;

(8) Diagnosis and elimination methods of system leakage (internal leakage, external leakage);

(9) Diagnosis and elimination of wear failure of hydraulic components;

(10) Diagnosis and elimination methods of speed control valve faults;

(11) The method of adjusting the electrical limit position;

(12) Analysis and elimination of electrical circuit faults;

(13) Practical training of hydraulic pipeline layout.

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.