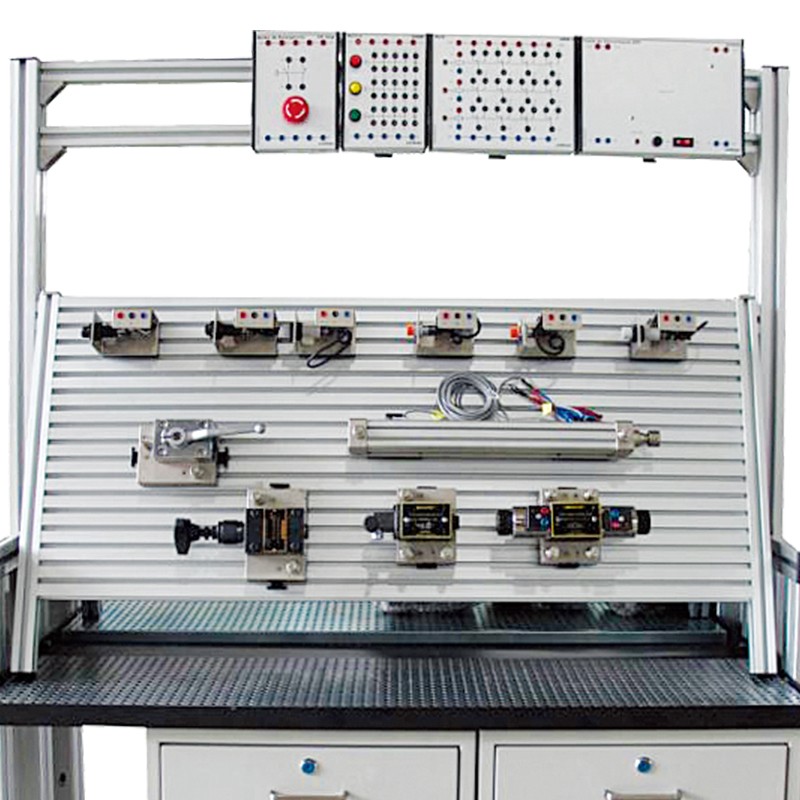

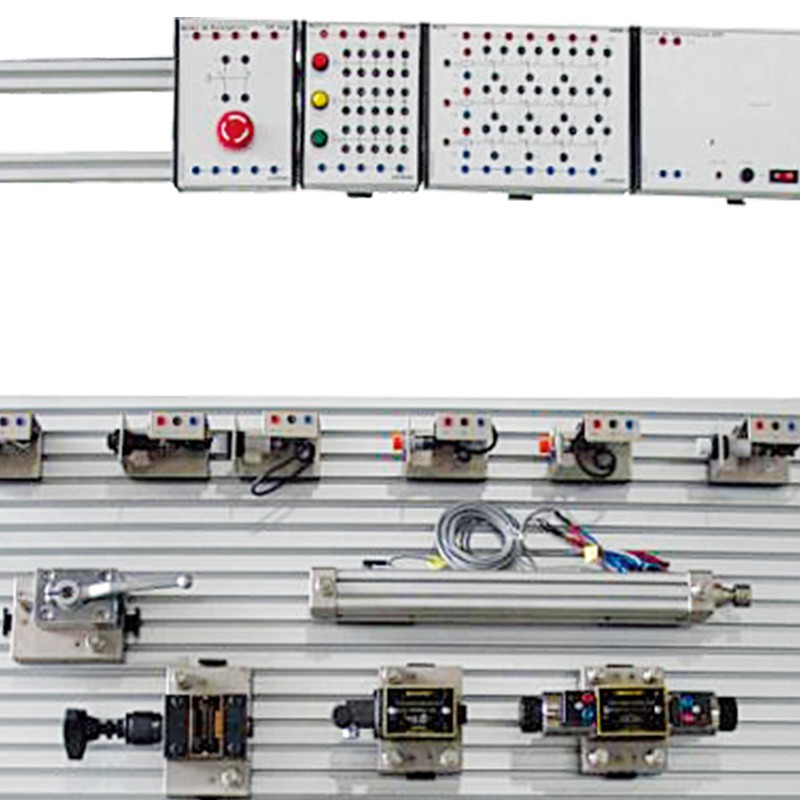

DLYQ-PH401 Double-sided Hydraulic Pneumatic Training Kits of vocational education equipment

- Dolang

- China

- 30-60DAYS

This training system integrates hydraulic, pneumatic, PLC electrical control and hydraulic simulation technology. In addition to meeting professional training and teaching, it can also carry out skill assessment and vocational skill competitions

DLYQ-PH401 Double-sided Hydraulic Pneumatic Training Kits of vocational education equipment

Equipment Overview

This DLYQ-PH401 Double-sided Hydraulic Pneumatic Training Kits of vocational education equipment integrates hydraulic, pneumatic, PLC electrical control and hydraulic simulation technology. In addition to meeting professional training and teaching, it can also carry out skill assessment and vocational skill competitions. Through project-based training, students are trained to install and install hydraulic pumping stations. Professional skills such as commissioning, hydraulic system assembly and commissioning, pneumatic system installation and commissioning, electrical control technology, PLC application technology, and hydraulic and pneumatic system operation and maintenance. Through actual operation experiments and course design, students can accurately grasp the structure of hydraulic components, control principles and design methods of hydraulic circuits, and practice hydraulic circuit optimization and hydraulic circuit troubleshooting through this device. It has strong practicability and operability.

Technical Parameters

1. Power supply: three-phase five-wire ~380V±10% 50Hz;

2. Working environment: temperature -10℃~40℃ relative humidity≤85%(25℃)

3. Device capacity: ≤2.5kW

4. Dimensions: 1600mm×880mm×1850mm

5. Aluminum alloy panel size: 1200 (length) × 750 (width)

Groove interval: 25mm

Aluminum wood cabinets: 2

Casters: 4

6. Air compressor Power supply: AC 220V±10% 50Hz, motor power: 600W

Nominal volume: 9L Rated output pressure 0.7MPa, noise level: 66dB

Training Content

Project 1. Hydraulic circuit construction and debugging training

1. Direction control loop

(1) Reversing circuit of manual reversing valve

(2) Reversing circuit of electromagnetic reversing valve

2. Pressure control loop

(1) Single-stage pressure regulating circuit

(2) Secondary pressure regulation

(3) Single-stage decompression circuit

(4) Secondary pressure reducing circuit

(5) Unloading circuit using "M" reversing valve

(6) Unloading circuit using reversing valve

(7) Pressure regulating circuit with overflow valve

(8) Pressure holding of hydraulic control check valve

3. Speed control loop

(1) Throttle speed regulation of the oil inlet

(2) Throttle and speed regulation of oil return

(3) Throttle and speed regulation by side oil circuit

(4) Speed synchronization circuit of speed control valve

(5) Parallel circuit of speed control valve

(6) Series circuit of speed control valve

4. Sequential action circuit using sequence valve

5. Sequential action loop controlled by travel switch

6. Sequential action loop controlled by pressure relay

7. Using hydraulic control check valve one-way blocking circuit

8. Using hydraulic control check valve two-way blocking circuit

9. Locking circuit with "O" type reversing valve

10. Relay control hydraulic basic circuit

11. Other self-built circuits

Project 2: Pneumatic circuit construction and debugging

Pneumatic basic control loop experiment;

Automatic control of single-acting cylinder;

Automatic control of double-acting cylinder;

Relay control technology application;

Other types of pneumatic circuits such as comprehensive and expandable experiments.

Examples of basic pneumatic experimental circuits:

(1) Reversing circuit of single-acting cylinder;

(2) Reversing circuit of double-acting cylinder;

(3) Single-acting cylinder speed control loop;

(4) One-way speed control circuit of double-acting cylinder;

(5) Double-acting cylinder two-way speed control circuit;

(6) Speed switching circuit;

(7) Buffer circuit;

(8) Secondary pressure control loop;

(9) High and low voltage conversion circuit;

(10) Delay loop;

(11) Overload protection circuit;

(12) Single cylinder single reciprocating control circuit;

(13) Single cylinder continuous reciprocating action circuit;

(14) Multi-cylinder sequential action circuit;

(15) Double cylinder synchronous action circuit;

(16) Or gate type shuttle valve application circuit;

(17) Application circuit of AND gate double pressure valve;

(18) Application circuit of quick exhaust valve;

(19) Application of magnetic induction proximity switch;

(20) Application of sensors in control systems;

(21) Relay control circuit.

Project 3. PLC programming and debugging training project

1. PLC instruction programming, learning of ladder diagram programming;

2. Learning and using PLC programming software;

3. PLC controls the reversing circuit of the electromagnetic reversing valve;

Project 4 Hydraulic and Pneumatic Simulation Teaching and Training Project

1. Introduction and working principle of hydraulic transmission;

2. Composition and function simulation of hydraulic system;

3. Operation and simulation of hydraulic circuit;

4. Design and simulation of hydraulic circuit;

5. Introduction to pneumatic transmission and simulation of working principle;

6. The composition and function simulation of pneumatic transmission;

7. Operation and simulation of pneumatic circuit.

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.