DLRB-1410WP Industry 4.0 6 Axis robot training Industrial Robot Welding Workstation Vocational Educational Equipment

- Dolang

- China

- 30-60 days

Teaching programming: Realize on-site programming through the teach pendant configured by the robot.

Fault self-diagnosis: Welding machines and robots judge various emergencies and try to repair them automatically.

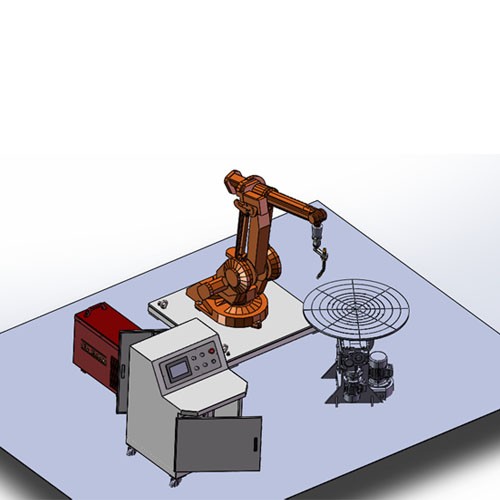

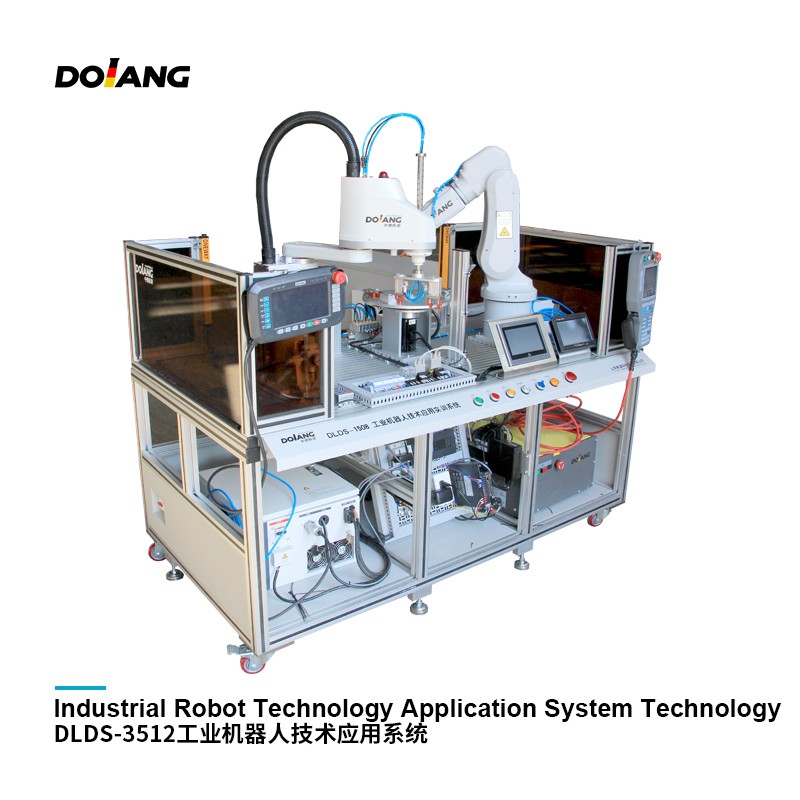

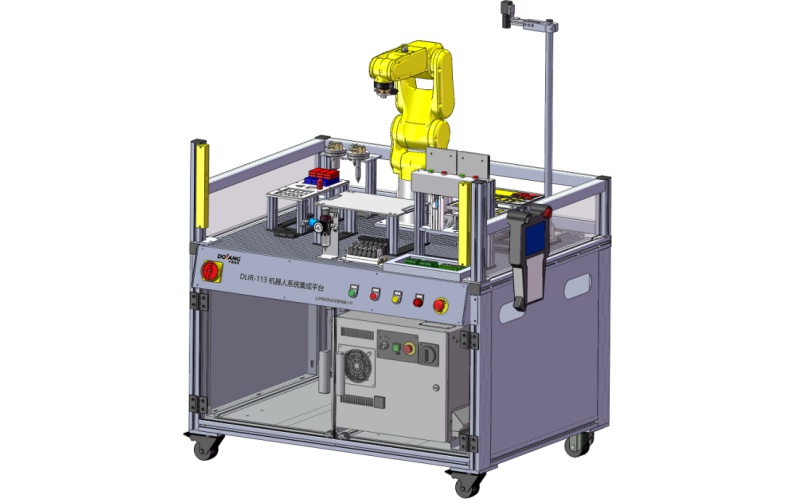

DLRB-1410WP Industry 4.0 6 Axis robot training Industrial Robot Welding Workstation Vocational Educational Equipment

Equipment Overview

DLRB-1410WP Industry 4.0 6 Axis robot training Industrial Robot Welding Workstation Vocational Educational Equipment is mainly composed of: industrial robot body, industrial robot controller, handheld teach pendant and control cable, welding power supply, wire feeder, wire feeder base, wire feed spool, supporting cable, welding gun, welding gun clamp It consists of holder, anti-collision sensor (optional), console, robot base, positioner, safety fence, etc.

Technical Parameters

1. Number of robot axes: 6 axes, expandable to 8 axes

2. Maximum load of the robot: 5 kg;

3. Maximum working radius of robot arm: 1.44m;

4. Repeated positioning accuracy of the robot: 0.025mm;

5. Electrical connections

Three-phase AC 400V (+10%, -15%), 50Hz, 7.68KVA

6. Environmental parameters

Ambient temperature: 5C- 45C

Relative humidity: 95%

Noise level: <70dB

7. Weight: 225 kg

Training Content

1. Understand the main components and working principles of welding robots;

2. Understand the supporting facilities around the welding robot;

3. Operation practice of robot welding;

4. Learn the application interface of welding software package;

5. Setting of welding process parameters of teach pendant;

6. Programming and storage of robot welding track;

7. Protective measures for welding robots;

8. Robot welding work range and welding gun posture adjustment;

9. Adjustment of the speed of each axis of the robot;

10. The protection mechanism of the welding gun and the location and parameters of the sensor;

11. Experimental adjustment of the parameters of arc ignition and arc closing for the second protection welding in the teach pendant;

12. Setting of welding gun wire cleaning program;

13. Factors affecting welding quality.

FAQ

Q1. What other services can Dolang provide besides teaching equipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.