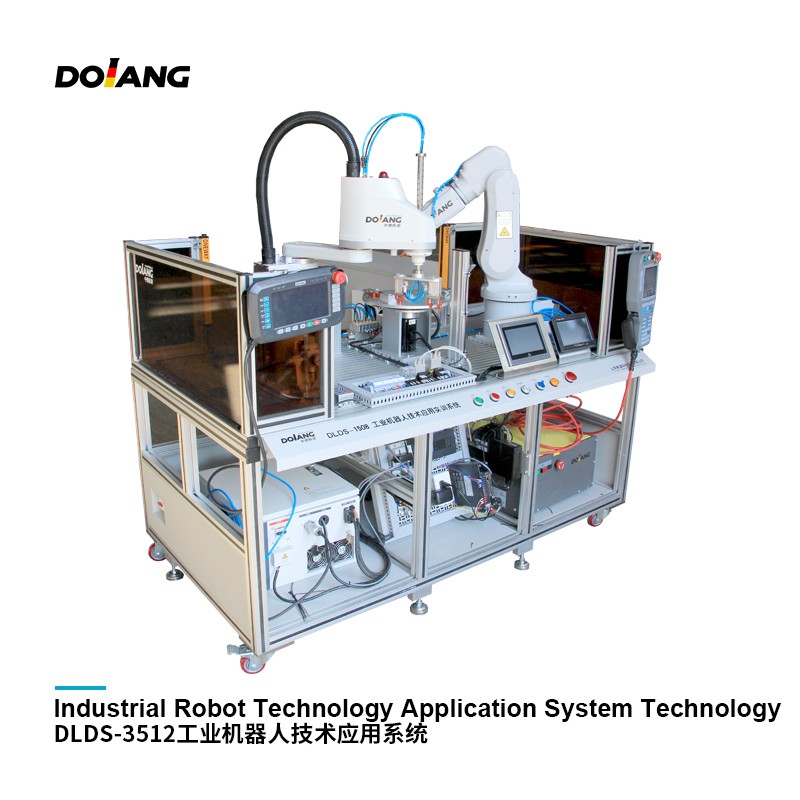

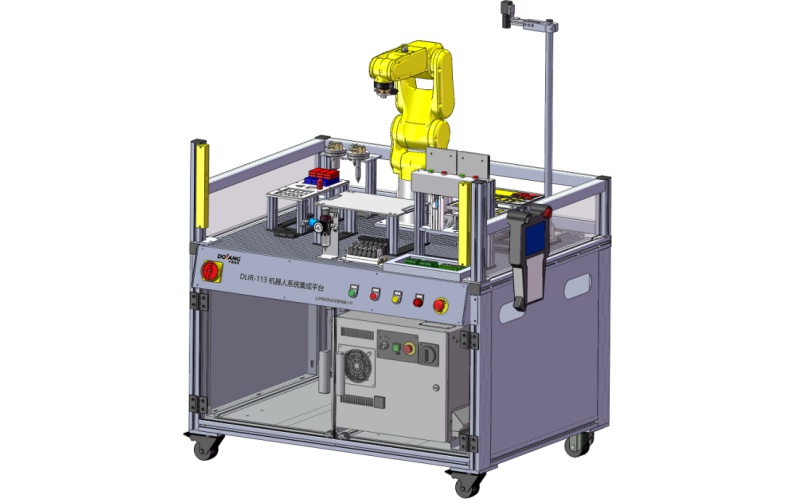

DLRB-1410A CNC Machining System Of Industrial Robot training equipment

- Dolang

- China

- 30-60 days

Offline programming is the best way to expand the robot system investment returns. It can complete robot programming in the office by ABB simulation and offline programming software RobotStudio with no need to break off the production. The robot procedure can be ready in advance to improve the overall production efficiency.

DLRB-1410A

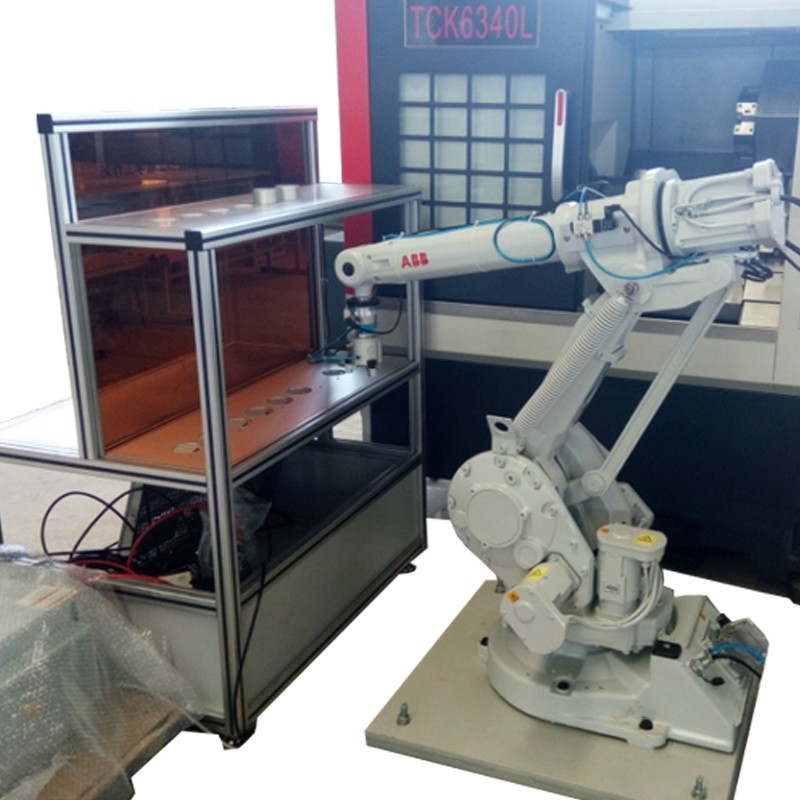

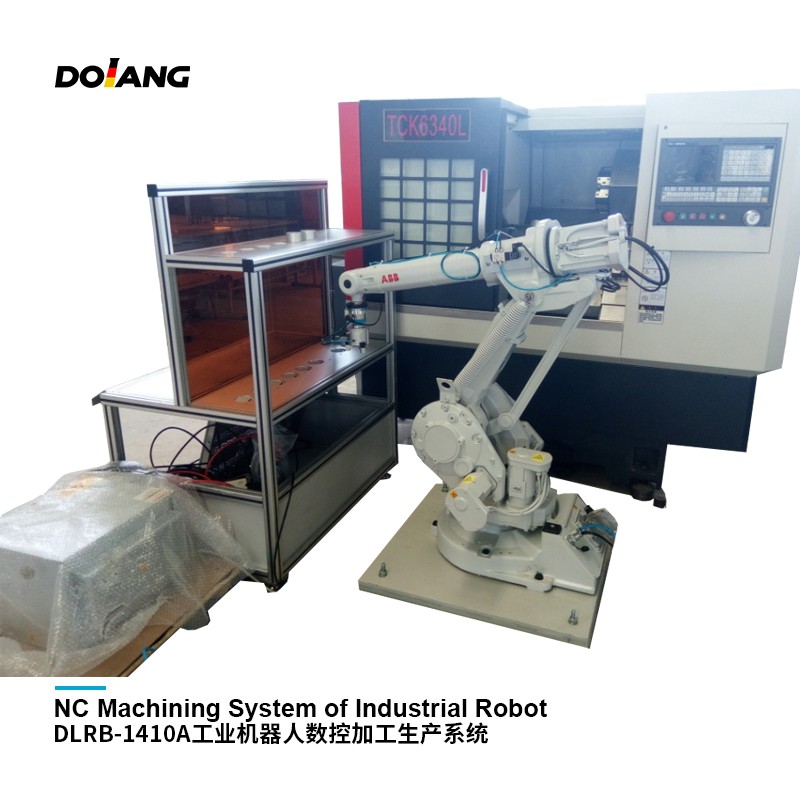

DLRB-1410A CNC Machining System Of Industrial Robot training equipment

Equipment Overview

a) DLRB-1410A CNC Machining System Of Industrial Robot training equipment, It seems to make the real robot into your PC computer by virtual robot technology offline programming!

b) Offline programming is the best way to expand the robot system investment returns. It can complete robot programming in the office by ABB simulation and offline programming software RobotStudio with no need to break off the production. The robot procedure can be ready in advance to improve the overall production efficiency.

c) It can perform training , programming, and optimization tasks by various tools provided by RobotStudio under the premise of not affecting the production. It can improve the profitability of robot system to let you get a variety of benefits.

Technical Parameters

1. Input power: three-phase four-wire 380V ± 10% 50HZ/60Hz

2. Working environment: temperature -10 ℃ - +40 ℃, relative humidity <85% (25 ℃), no water beads condensation altitude <4000m

3. Power control: automatic air switch off power, with overvoltage protection, undervoltage protection, overcurrent protection, leakage protection system.

4. Output power:

(1) Three-phase four-wire 380V ± 10% 50HZ. Controlled by the start switch and protected by a fuse

(2) DC power supply: 24V / 1A.

5. CNC lathe: Full-function slant bed CNC lathe machine

6. Robot: ABB IRB1410

Training Content

Industrial robot learning and training

1. Basic Principles and Constitution of Industrial Robots

2. Cognition of Industrial Robot Ontology

3. Industrial robot electrical part cognition

4. Industrial robot software cognition

5. Servo motor and driver recognition

6. Robot reducer cognition

7. Industrial robot controller cognition

8. Kinematics analysis and control of industrial robots

9. Six-degree-of-freedom robot joint motion control learning and training

10. Six-degree-of-freedom robot linear motion trajectory control learning and training

11. Six-degree-of-freedom robot circular motion track control learning and training

12. Six-degree-of-freedom robot acceleration and deceleration constraint control learning and training

13. Robot control basic operation training

14. Robot coordinate system (tool coordinates, user coordinates) application operation training

15. Robot operation and teaching programming training

16. Typical application of robots - application examples for machine loading and unloading

17. Typical Application of Robots - Parts Assembly Application Examples

18. Typical application of robots - examples of visual applications

19. Robot acceptance and accuracy measurement training

20. Robot maintenance training

21. Robot hand grasping, training platform tooling design

CNC lathe learning and training

1. Machine tool principle and structure learning

2. CNC machine tool classification and function

3. CNC system learning

4. CNC machine tool application technology

5. CNC machine operation and programming

6. Structural design of CNC machine tools

7. Electrical system design of CNC machine tools

8. Machine tool table fixture design

Virtual industrial robot workstation learning and training

1. Principle Cognition of Virtual Industrial Robot Training System

2. Virtual industrial robot training system software learning

3. Virtual industrial robot training system training operation

4. Six-degree-of-freedom robot joint motion control learning and training

5. Six-degree-of-freedom robot linear motion trajectory control learning and training

6. Six-degree-of-freedom robot circular motion track control learning and training

7. Six-degree-of-freedom robot acceleration and deceleration constraint control learning and training

8. Robot control basic operation training

9. Robot coordinate system (tool coordinates, user coordinates) application operation training

10. Robot operation and teaching programming training

11. Typical application of robots - example of machine loading and unloading application scenarios

12. Typical application of robots - examples of handling application scenarios

Electrical technique training

1. Installation and commissioning of electrical circuits

2. Servo motor characteristics and applications

Fault test training

1. Find modified program failure training

2. Troubleshooting parameter failure training

3. Electrical wiring failure troubleshooting training

4. Mechanical failure troubleshooting training

Hydraulic & Pneumatic Technology

1. Learning of hydraulic and pneumatic control principles

2. Calculation and design of hydraulic and pneumatic control

3. Installation and commissioning of hydraulic and pneumatic control circuits

4. Working principle and application of electronically controlled pneumatic valve

5. Working principle and application of vacuum generator

6. Working principle and application of gas source components

7. Types, working principle and application of cylinders and grippers.

FAQ

Q1. What other services can Dolang provide besides teaching equipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.