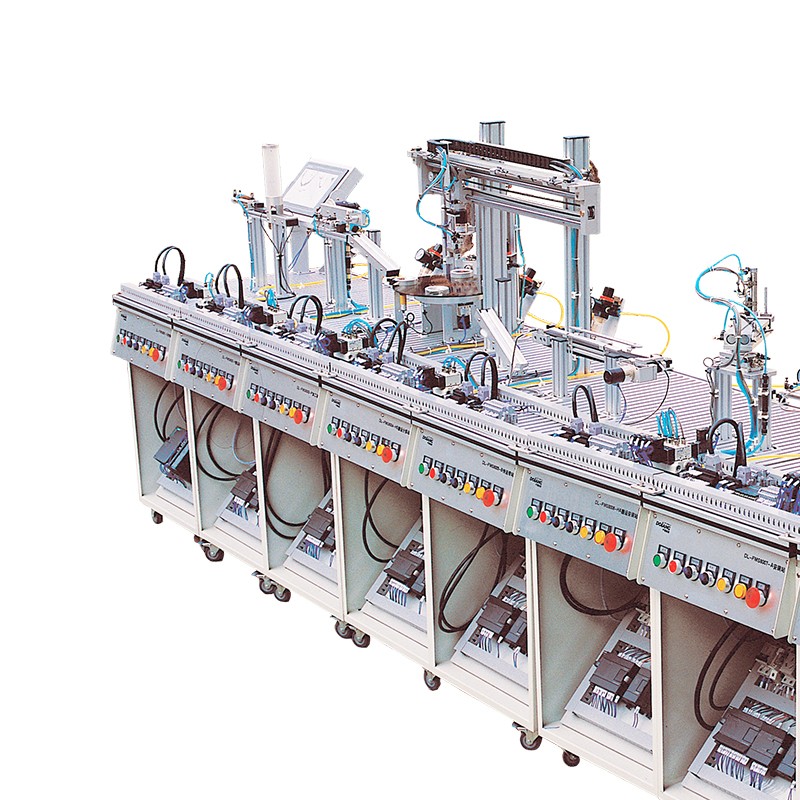

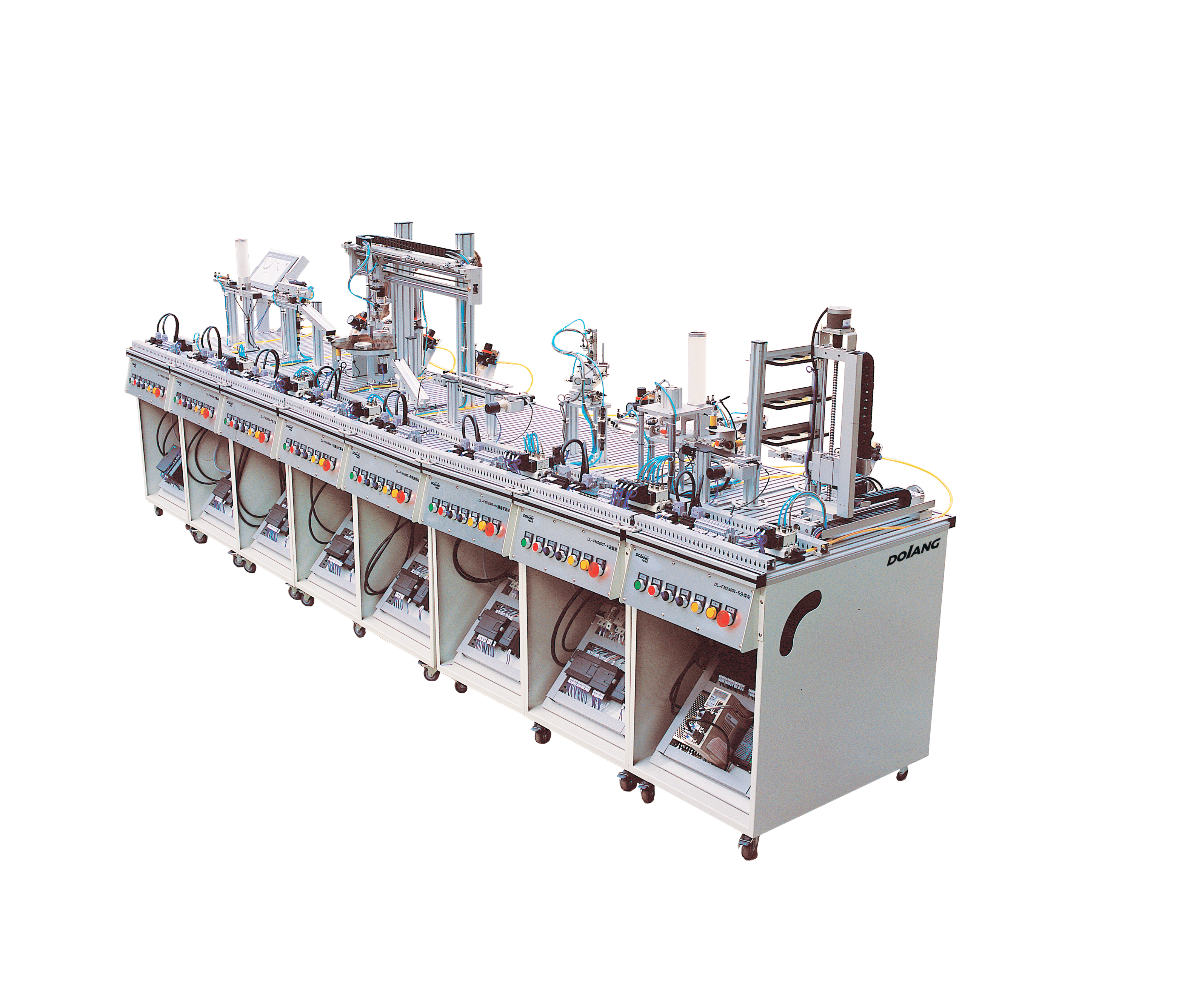

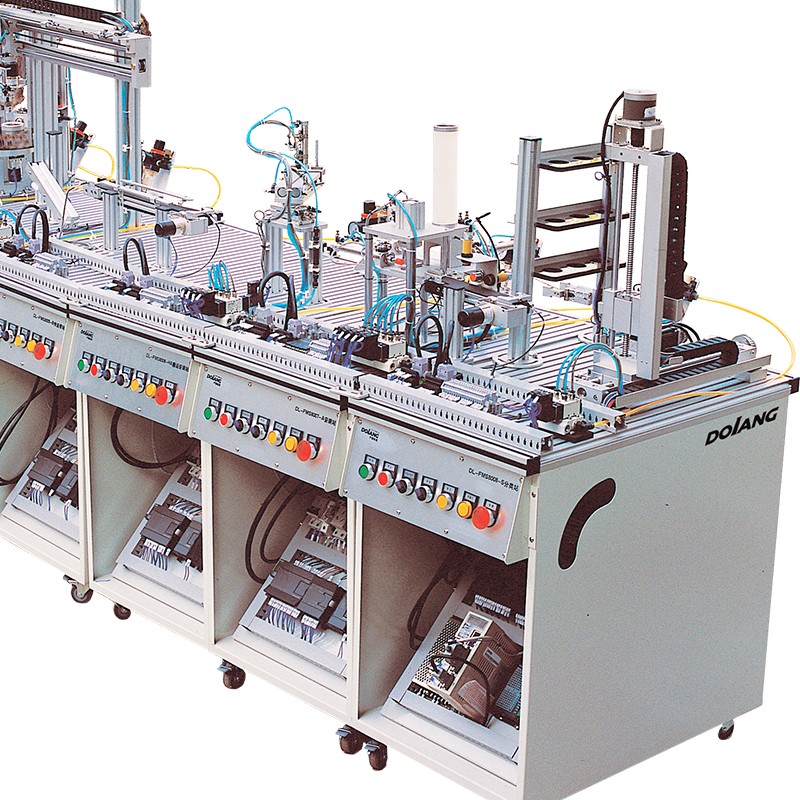

DLMPS-800A MPS Machatronics Training system of Industry 4.0

- Dolang

- China

- 30-60DAYS

1. Instictive: Main equipment use directly exposed installation form, the device can be more intuitive to show to students, shortening the adaptation time of students from the classroom to the industrial site.

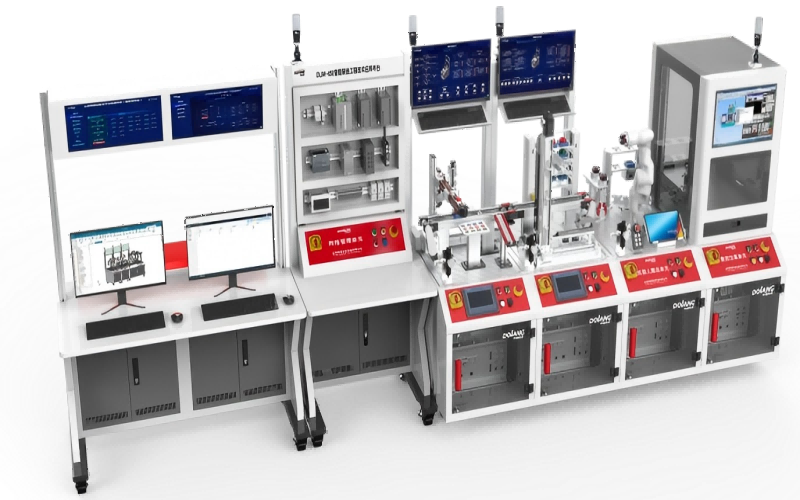

2. Networking: PROFIBUS-DP acting as main line of network control system, the field device control layer act as a secondary line, the entire device follow the command of the supreme commander, while allowing each branch independently finish assigned tasks. The general control station is the leader of device and each unit is branch.3. Advanced technology: the device combines industrial practical control requirement, based on module design, use technologies like PLC control technology, sensor technology, optical technology, mechanical transmission technology, pneumatic technology, servo control technology, stepper control technology etc, provide extensive practical training to students.

4. Comprehensive: Master control station stands for focus thinking, and each sub-station stands for divergent thinking, they can work indepently and also can group management.

5. PC configuration: through the computer platform, combine various sub-station via configuration principle, each station will be controlled together by the teacher machine.

6. Easy to operate: Each work unit both can indepently operate and can be combined to network operation

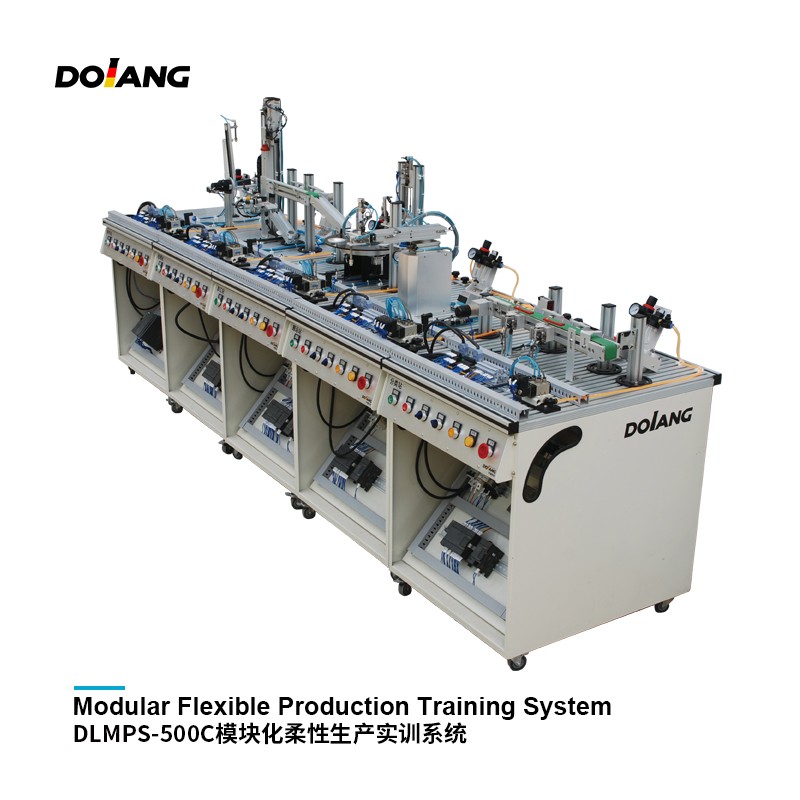

DLMPS-800A MPS Machatronics Training system of Industry 4.0 production system

Equipment Overview

The DLMPS-800A MPS Machatronics Training system of Industry 4.0 is involved with technologies like PLC control technology, sensor detecting technology, pneumatic technology, motor drive technology,servo drive technology, stepper drive technology, PC configuration monitor and human-PC interface, mechanical structure and system installation debugging, default testing technology, PROFIBUS technology, touch screen technology, motion control, PC technology and system engineering etc.

Technical Parameters

1.Input power supply: 1 phase~220V±10% 50HZ

2. Leakage protection: I△n≤30mA, t≤0.1S

3. AC220V AC power supply

4. Control power: DC24V

5.Emergency stop button,power indicator,power supply indicator

6. Electric protection of power off by mistake

7.Working environment: temperature -10℃~+40℃ relative humidity 35%~65%(25℃) Altitude<4000M

8. Capacity: ≤5kVA

9. Air pressure range: 0.4~0.6Mpa

10. Dimension: 790×3600×1280mm.The height of table is 750mm

Single station dimension: 790×450×750mm

Training Content

1. Cognition and application of pneumatic technology

●Understanding of air pump

●Awareness of air source processor

●The perception of filters

●Awareness and application of vacuum generator

●Awareness of various cylinders (swing cylinder, double rod cylinder, etc.)

●Awareness and application of solenoid valve

●The perception and application of sensors

●Connecting cognition of trachea

●Cognition of adjusting joints

●Installation and debugging of solenoid valve

●Installation and debugging of cylinder

●Installation and debugging of air source treatment

●Maintenance and maintenance of various cylinders

●Maintenance and maintenance of various solenoid valves

2. Cognition and application of sensor technology

●Cognition and application of photoelectric sensor

●Cognition and application of optical fiber sensor

●The cognition and application of magnetic sensor

●Cognition and application of current sensor

●Recognition and application of vortex proximity switch

●Wiring method of various sensors

●Fault judgment and maintenance of various sensors

●Wide application of various sensors in industrial scene

3. Cognition and application of mechanical transmission technology

●Cognition and application of belt

●Cognition and application of gears

●The recognition and application of cylinder

●Recognition and application of ball screw

4. The principle and application of industrial automation technology

●The principle and application of PLC

●PLC programming method and application

●PLC programming method for loading station

● PLC programming method of operating station

● PLC programming method of processing station

●PLC method for programming and installing transfer station

●The method of PLC programming and installation unit station program

●The method of PLC programming for three-dimensional storage station

● PLC programming method of handling unit station

● PLC programming method of conveyor belt work unit station program

●PLC network programming method

●Comprehensive programming method for each station

5. Cognition and application of DLMPS-800A modular production line

●Feeding station application

●Transport station application

●Application of processing station

●Application of handling and sorting station

●Application of transfer station

●Application of handling installation station

●Application of assembly station

●Application of classification station

●Relations and applications between stations

●Practical training of systematic comprehensive ability

6. Through system training, enable students to master the following skills:

●Application of production process

●Application of mechanical and pneumatic components assembly

●Understand how to select and apply electrical appliances

●Application of Pneumatic Technology

●Application of various sensors

●The design of electrical schematic diagram and the standard requirements of component symbols

●Understand how to reasonably arrange and wire the board

●Installation of various sensors and adjustment of sensitivity, understand how to judge the quality of sensors and accident handling methods;

●System debugging technology: cylinder debugging; motor trial operation; mechanical position debugging; sensor debugging; collection of various signals; single station debugging and network debugging, etc.;

●Equipment fault diagnosis and maintenance

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.