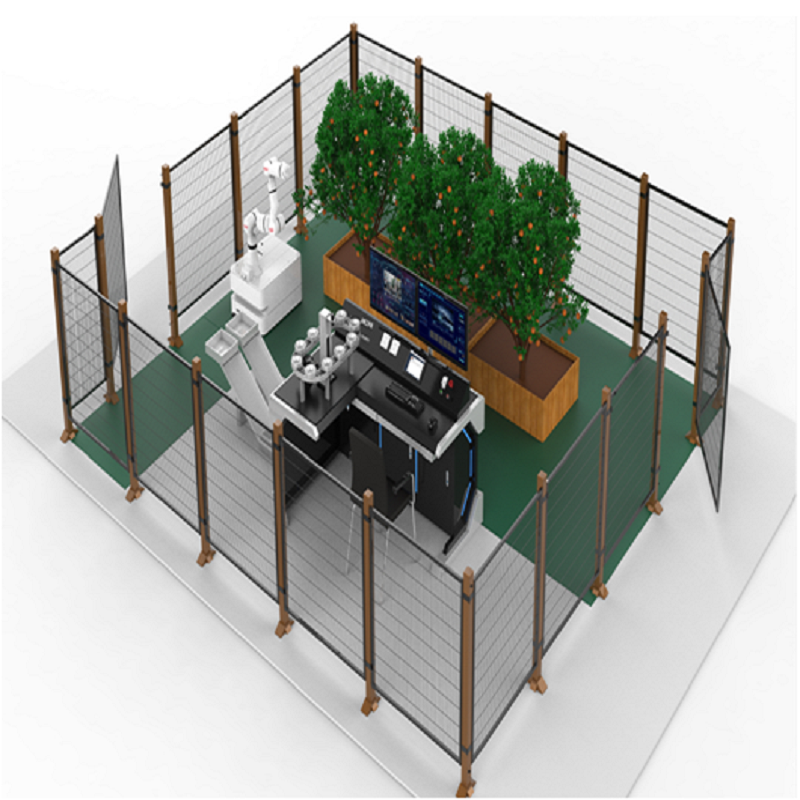

DLIM-44 Intelligent manufacturing system integration training platform

- Dolang

- China

- 40-60 days

DLIM-44 Intelligent manufacturing system integration training platform belong to TVET technical training equipment, the teaching system is mainly composed of CNC processing station, intelligent logistics station, industrial robot station and intelligent storage station. Different combination formations such as lining up, L shape, T shape or Square shape can be made according to site or customer requirements.

Users can inquire about intelligent warehousing, equipment information, tool magazine information, workpiece inspection results, processing quality and other information through the production management system software of the touch screen all-in-one machine, and they can perform scheduling of inserting orders and scheduling for different product production. the engineer teaching system is ideal for technical training.

1. Overview

DLIM-441 Intelligent manufacturing system integration platform is a vocational education equipment, which is modeled on discrete digital manufacturing enterprises, deploys basic nodes of the Internet of Things such as smart cameras, online measurement, RFID and network equipment at the data collection layer; introduces industrial robots, AGVs, and intelligence at the equipment execution layer Intelligent manufacturing equipment such as warehousing and CNC machine tools; introduces digital twins and MES manufacturing execution systems in the management and control layer; meanwhile, it also builds an open information service platform, shares data resources, and finally realizes the automation, digitization, networking and intelligence of the entire system.

This technical training equipment is mainly composed of CNC processing station, intelligent logistics station, industrial robot station and intelligent storage station. Different combination formations such as lining up, L shape, T shape or Square shape can be made according to site or customer requirements.

Users can inquire about intelligent warehousing, equipment information, tool magazine information, workpiece inspection results, processing quality and other information through the production management system software of the touch screen all-in-one machine, and they can perform scheduling of inserting orders and scheduling for different product production.

2. Technical Parameter

Model: DLIM-441

CNC System: KND K1000MC industrial-grade CNC system

Input Power Supply: single-phase three-wire system, AC220V ± 10%, 50HZ

Output Power Supply: DC24V

Machine Capacity: approximately 8KW.

Working Environment: temperature of 0℃ -40℃, relative humidity of <85% (25℃) and no bead condensation altitude of <4000m

Recommended Working Air Pressure: 0.3-0.7MPa.

Equipment Footprint: approximately 7m.52. The actual design size shall prevail.

Safety Protection Function: emergency stop button, limiter, Protective cover for processing, warning light, etc.

3. Experimental Projects

1)Installation and application of PLC programming software

2)Installation and application of HMI touch screen programming software

3)Installation, debugging, programming and application of the robot

4)Installation, debugging and application of robot clamps

5)Installation and application of robot offline programming software

6)Application of CNC processing center assembly, maintenance and programming

7)Application of online measurement system installation and programming

8)Application of visual inspection technology

9)Communication debugging and application of AGV trolley

10)Application of bus communication technology

11)Application of industrial automation network

12)Application of PLC technology

13)Application of motor drive control technology

14)Application of motion control system

15)Use of instruments

16)Application of MES production management execution software

17)Application of intelligent manufacturing virtual simulation technology

Safe production, etc.

4. FAQ

Q1. What kind of price terms we can choose ?

Dolang provide EXW, FOB, CIF, CFR and other price terms based on communication.

Q2. What is the payment terms ?

TT or LC at sight, all payments are released before delivery.

Q3. What is the lead time?

Dolang provide a 50days lead time for clients, if you have special demands, pls communicate with project manager.

Q4. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.