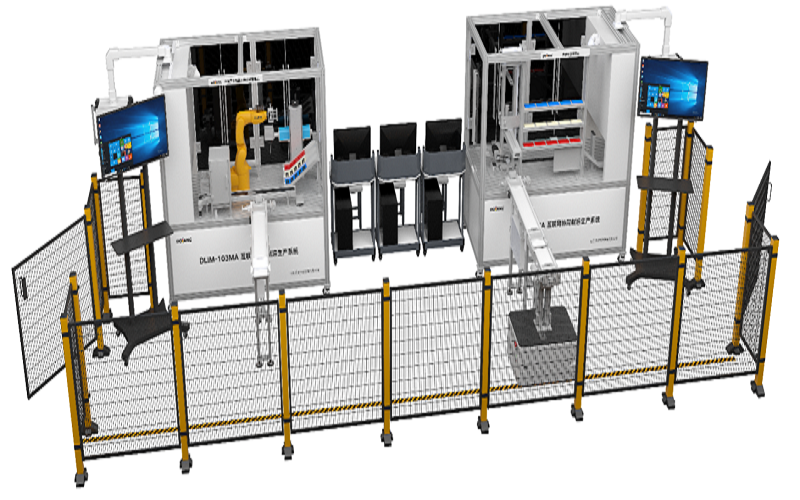

DLIM-103MA Internet collaborative manufacturing training system

- DOLANG

- CHINA

- 40-60DAYS

DLIM-103MA Internet collaborative manufacturing training system is up to date industrial 4.0 technical training system, which is composed of network layer suite, training platform, bookmark feeding module, industrial visual inspection module, six axis industrial robot handling and assembly module, Bookmark Box feeding module, RFID tag reading and writing unit, automatic storage module, AGV mobile car and control system. The software platform consists of MES production information management system.

1. Overview

DLIM-103MA Internet collaborative manufacturing training system is an industry 4.0 training system, which is composed of network layer suite, training platform, bookmark feeding module, industrial visual inspection module, six axis industrial robot handling and assembly module, Bookmark Box feeding module, RFID tag reading and writing unit, automatic storage module, AGV mobile car and control system. The software platform consists of MES production information management system.

Using this system, students can learn and master the following skills:

1) Sensor detection technology: including photoelectric sensor, optical fiber sensor, inductance sensor and so on. Students can know and understand each sensor and master the use method of each sensor on the equipment.

2) Visual inspection technology: students can know and understand the visual inspection equipment, master the use of visual inspection equipment, and practice the use of visual inspection software.

3) Visual dynamic tracking and picking technology: students can understand and account for the composition and application of visual dynamic tracking technology through conveyor, visual inspection system, rotating card, sensor and processing software.

4) Electrical control system: electrical drawings are designed according to industrial standards. Students can learn circuit principle analysis, PLC I/O address checking and equipment circuit analysis methods on the equipment.

5) Motor drive technology: including DC motor, servo motor and driver, etc. students can understand the motor and master the use method of each motor.

6) Industrial robot technology: students can know and understand the real industrial robot, learn the use of industrial robot, and practice the software programming of industrial robot.

7) Siemens PLC technology: students can practice PLC wiring, programming, debugging on the equipment.

8) Configuration technology: students can practice Siemens configuration software programming and communication between configuration software and PLC.

9) Process flow of production line: students can learn the process flow of production line on the equipment.

10) System maintenance and fault detection technology: this part focuses on the contents and methods of routine maintenance of electromechanical integration equipment, as well as common fault analysis and troubleshooting methods.

11) MES technology and application: users place orders through computers or mobile phones, select demand information at the same time (demand information is provided in the form of multiple options, users can choose bookmarks and packaging boxes with different colors), upload customized pictures, and send order information to Internet collaborative manufacturing production line through MES system.

2. Technical Parameter

1. Working Power Supply: AC220 V ± 10%, 50 Hz.

2. Floor Space: 7.6 × 3.5 × 2.02m (L × w × h overall layout size)

3. Working Environment: temperature 5 ℃ - + 40 ℃, relative humidity < 85% (25 ℃).

4. Safety Protection: with short circuit, overload, sound and light alarm light, emergency stop multiple protection.

5. PLC: Siemens s7-1200 series.

6. Six Axis Industrial Robot:

Maximum load: 3kg

Axis J1: maximum operating range: ± 170 °;

J2 axis: maximum operating range: + 50 ° to - 170 °;

J3 axis: the maximum range of action is + 155 ° to - 110 °;

J4 axis: maximum operating range: + 175 ° to - 175 °;

J5 axis: maximum operating range: + 120 ° to - 120 °;

J6 axis: maximum operating range: + 350 ° to - 350 °;

Maximum working radius: 541 mm

Relocation accuracy: ± 0.02mm

3. Training Projects

1) Communication between PLC and remote I / O module;

2) The communication between PLC and six axis industrial robot is TCP / IP;

3) PROFINET communication between PLC and RFID;

4) PROFINET communication between PLC and PLC;

5) Wireless communication between PLC and AGV car;

6) Communication between MES and PLC;

7) Industrial robot installation, debugging and programming;

8) HMI and servo application;

9) Application of bus communication technology;

10) Application of industrial automation network;

11) The application of PLC technology;

12) The application of motor drive technology;

13) The application of vision technology;

14) The application of motion control system;

15) AGV car control system application;

16) Application of laser marking technology;

17) The application of MES system.

4. FAQ

Q1. What other services can Dolang provide besides teaching equipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of packages for delivery it is?

Dolang usually adapt wooden box to pack equipment and ensure the safety of equipment, it is shipped as a whole instead of shipped with spares.

Q3. What is the lead time?

Dolang provide a 50days lead time for clients, if you have special demands, pls communicate with project manager.

Q4. Whats the after sales service contents?

Dolang provide 24 hours online support for user, it is free within 1st year,

if there is no spares changes demands.