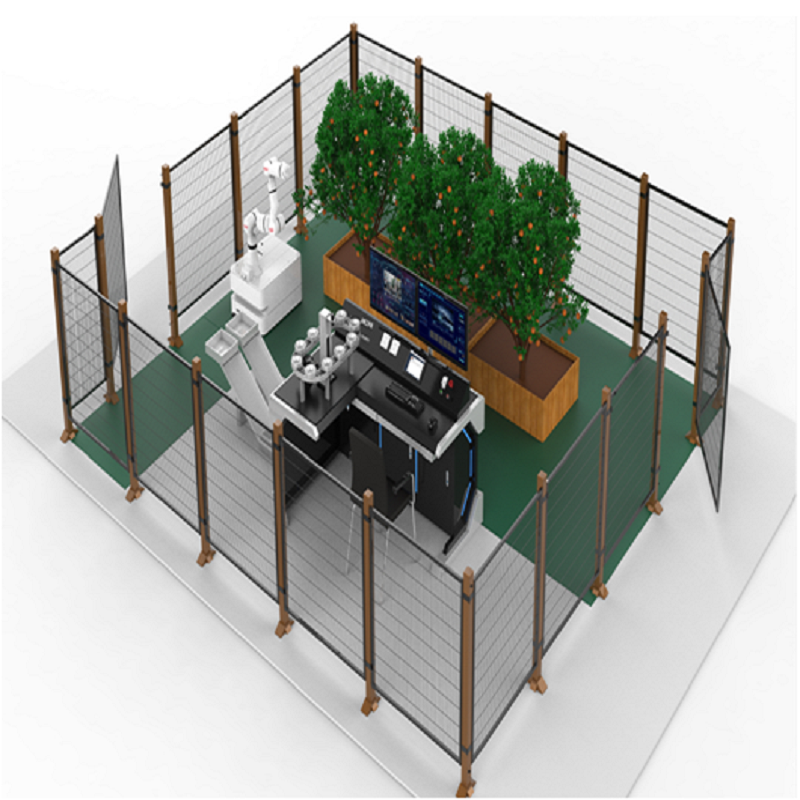

DLIM-102MA Industry 4.0 Smart Factory Training System

- DOLANG

- CHINA

- 40-60DAYS

DLIM-102MA Industry 4.0 Smart Factory Training System is one kind of latest up-to-date TVET intelligent technical training equipment, the smart technical teaching equipment is mainly used to demonstrate the production and assembly process of industrial automatic product line. Including warehouse feeding unit, 4 axis robot sorting unit, 6 axis industrial robot assembly unit, transport unit, MES system training unit.

I. Overview

DLIM-102MA Industry 4.0 Smart Factory Training System is a vocational training equipment, which is mainly used to demonstrate the production and assembly process of industrial automatic product line. Including warehouse feeding unit, 4 axis robot sorting unit, 6 axis industrial robot assembly unit, transport unit, MES system unit.

II. Technical Parameter

1. Working Power: AC220V ± 10%, 50HZ.

2. Dimensions: (length x width x height) 12000mmX5000mmX2200mm (the overall layout size)

3. Working Environment: temperature -10 ℃ - +40 ℃, relative humidity <85% (25 ℃).

4. Safety Protection Device: emergency stop button.

5. PLC: Siemens S7-1200 series.

6. Four-Axis Industrial Robots:

J1 axis: arm length: 225mm

Rotation range: ± 132º

Repeatability accuracy: ± 0.01mm

J2 axis: arm length: 175mm

Rotation range: ± 141º

Repeatability accuracy: ± 0.01mm

J3 axis: stroke 150mm

Repeatability accuracy: ± 0.01mm

J4 axis: Rotation range: ± 360º

Repeatability accuracy: ± 0.01mm

Rated / maximum load: 1Kg / 3Kg

Encoder module: Input 2-channel differential input incremental encoder

7. Six-Axis Industrial Robots:

J1 axis: maximum operating range: ± 170º

Maximum speed: 450 ° / S

J2 axis: maximum range of motion: -135 º ~ +80 °

Maximum speed: 380 ° / S

J3 axis: maximum operating range: -136 º ~ +270 °

Maximum speed: 520 ° / S

J4 axis: maximum operating range: ± 190º

Maximum speed: 550 ° / S

J5 axis: maximum operating range: ± 120º

Maximum speed: 550 ° / S

J6 axis: maximum operating range: ± 360º

Maximum speed: 1000 ° / S

Maximum working radius: 541mm

Repeatability accuracy: ± 0.02mm

III. Training Projects

1.PLC and remote I/O module communication;

2.Modbus-Tcp Communication between PLC and Four-axis Industrial Robot

3.PLC and Six-axis Industrial Robot TCP/IP Communication

4.PLC and servo drive Modbus-rtu communication

5.PLC and RFID Profinet Communication

6.Profinet communication between PLC and PLC

7.Communication between MES and PLC

8.Communication between AGV and PLC

9.Industrial robot installation, debugging and programming;

10.HMI and servo applications;

11.Application of Bus Communication Technology

12.Industrial automation network applications;

13.Application of PLC technology;

14.Application of motor drive technology

15.Application of visual technology

16.Application of motion control system;

17.AGV car control system application;

18.Application of laser marking technology;

19.Application of MES system.

IV. FAQ

Q1. What kind of price terms we can choose ?

Dolang provide EXW, FOB, CIF, CFR and other price terms based on communication.

Q2. What is the payment terms ?

TT or LC at sight, all payments are released before delivery.

Q3. What is the lead time?

Dolang provide a 50days lead time for clients, if you have special demands, pls communicate with project manager.

Q4. Whats the after sales service contents?

Dolang provide 24 hours online support for user, it is free within 1st year,

if there is no spares changes demands.