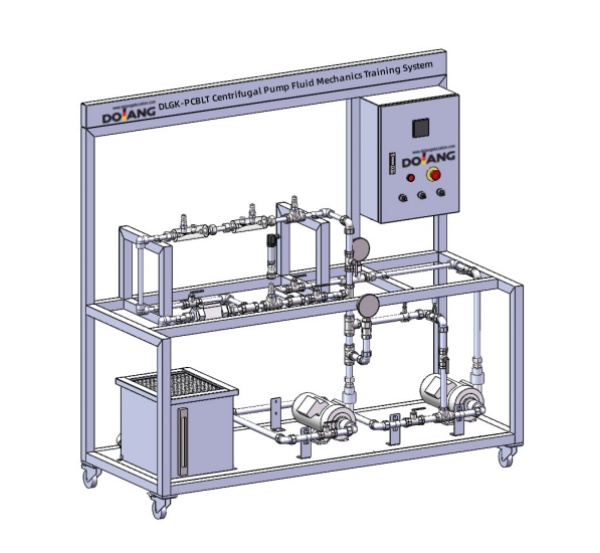

DLGK-PCBLT Centrifugal Pump Fluid Mechanics Training System

- Dolang

- China

- 30-60 Days

Centrifugal pump series -parallel and fluid mechanics education equipment is mainly composed of electrical control system, centrifugal pump, test bench, water tank, valve, venturi tube, detection sensor, etc.

The centrifugal pump series and parallel and fluid mechanics educational equipment is a physical simulation object based on the industrial process. The teaching table is mainly used to complete the series and parallel experiments of centrifugal pumps by adjusting different centrifugal pumps and valve switches, complete the Venturi tube experiment by adjusting different centrifugal pumps and valve switches, and complete the measurement of parameters such as pressure through the coordination of different components.

Pictures are for reference only

1. System Overview

Centrifugal pump series -parallel and fluid mechanics education equipment is mainly composed of electrical control system, centrifugal pump, test bench, water tank, valve, venturi tube, detection sensor, etc.

The centrifugal pump series and parallel and fluid mechanics educational equipment is a physical simulation object based on the industrial process. The teaching table is mainly used to complete the series and parallel experiments of centrifugal pumps by adjusting different centrifugal pumps and valve switches, complete the Venturi tube experiment by adjusting different centrifugal pumps and valve switches, and complete the measurement of parameters such as pressure through the coordination of different components.

2. Main technical parameters of the system

1. Input voltage: single-phase three-wire AC 220V±10% 50H z

2. Working environment: Ambient temperature range is 0 ~ 40℃

3. Device capacity: AC < 2000 VA

4. Safety protection: leakage protection (operating current ≤ 2 0mA), overcurrent protection

5. Relative humidity: ≤90% (25 ℃)

6. Floor space: 1720mm*670mm*1640mm (length*width*height)

3. System module composition and functions

In the system pipeline is water . The combination of two centrifugal pumps and multiple valves is used to realize the series and parallel connection of centrifugal pumps and the Venturi experiment . The series connection of centrifugal pumps can increase the head without changing the flow rate, while the parallel connection of centrifugal pumps can ensure that the flow rate in the pipeline is increased without changing the head.

Workflow:

(1)Series process: The water in the water tank is pumped out by water pump A through ball valve A and ball valve B, and returns to the water tank through ball valve E, water pump B, ball valve F, and ball valve G. When the water flows through the pipeline, a measuring port is opened at the corresponding position of the pipeline to facilitate the user to measure the pressure parameters.

(2)Parallel process: The water in the water tank is pumped out by pump A through ball valves A and B, and then pumped out by pump B through ball valves A and C. The water from pump A passes through ball valve D and converges with the water from pump B through ball valve F, and then returns to the water tank through ball valve G. When the water flows through the pipeline, a measuring port is opened at the corresponding position of the pipeline to facilitate the user to measure the pressure parameters.

(3)Venturi experiment: The water in the water tank is pumped out by water pump A through ball valve A and ball valve B, and returns to the water tank through ball valve H, Venturi tube A, and Venturi tube B in sequence. When the water flows through the pipe, a measuring port is opened at the corresponding position of the pipe to facilitate the user to measure the pressure parameters.

IV. List of main equipment

No. | Name | Model Specifications | QTY | Remark |

1 | Training platform | Sheet Metal | 1 |

|

2 | Water tank | ≥30L | 1 |

|

3 | Ball valve Q20 | Q20 | 5 |

|

4 | Ball valve Q25 | Q25 | 4 |

|

5 | Venturi tube | PVC or equivalent | 2 |

|

6 | Pressure gauge | 0~0.16Mpa | 2 |

|

7 | Water Pump | MP-120RM/220V | 2 |

|

8 | Digital pressure gauge | Power supply DC24V, output 0-10V | 1 |

|

9 | Quick Connectors | Contains two spare parts | 6 |

|

10 | pipeline | Stainless steel | 1 |

|

11 | breaker | 2P 10A | 1 |

|

12 | Manual knob | 1 open 1 closed | 2 |

|

13 | Solenoid valve | AC220V | 1 |

|

14 | AC contactor | AC220V, 9A | 2 |

|

15 | Switching Power Supply | DC24V, 3A | 1 |

|

5. Experimental Project

Training 1: Experimental cognition of pump series connection

Training 2: Parallel Experimental Understanding of Pumps

Training 3: Venturi Experiment Cognition

Training 4: Pressure gauge experimental cognition

Training 5: Experimental Understanding of Digital Pressure Transmitter

Training 6: Valve Comprehensive Experimental Cognition