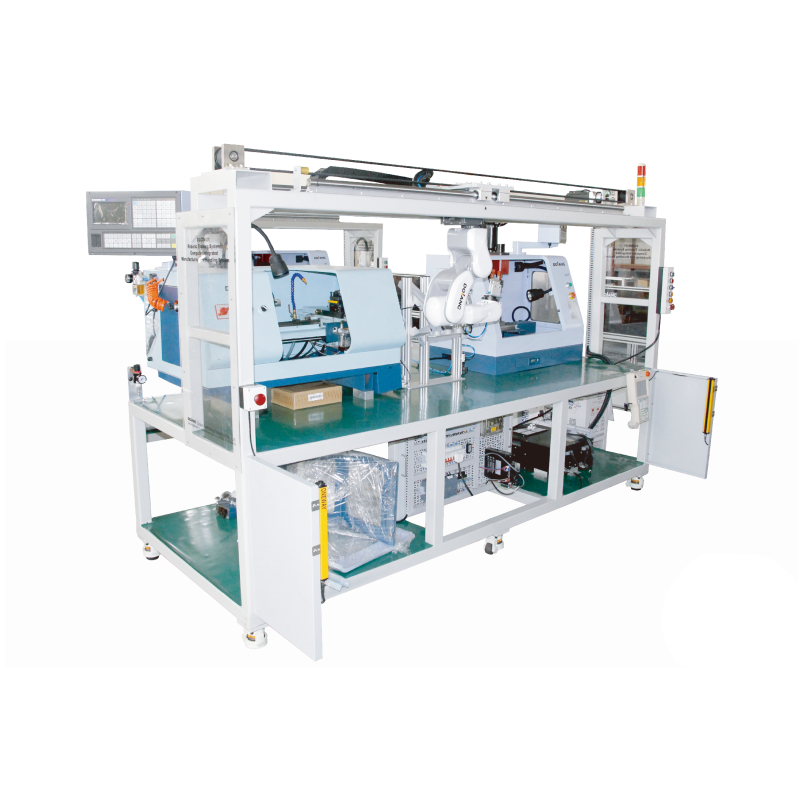

DLCIM-01 Computer Integrated Manufacturing Training System

- Dolang

- China

- 40-60 days

DLCIM-01 Computer Integrated Manufacturing Training System is an industry 4.0 teaching system and vocational training equipment,not only to meet the requirements of professional teaching, but also can exercise students to a variety of disciplines and comprehensive use of knowledge and system thinking ability.

This training system integrate industrial robots, programmable controllers, servo motors, sensors and organic integration in one of the training system

1. Overview

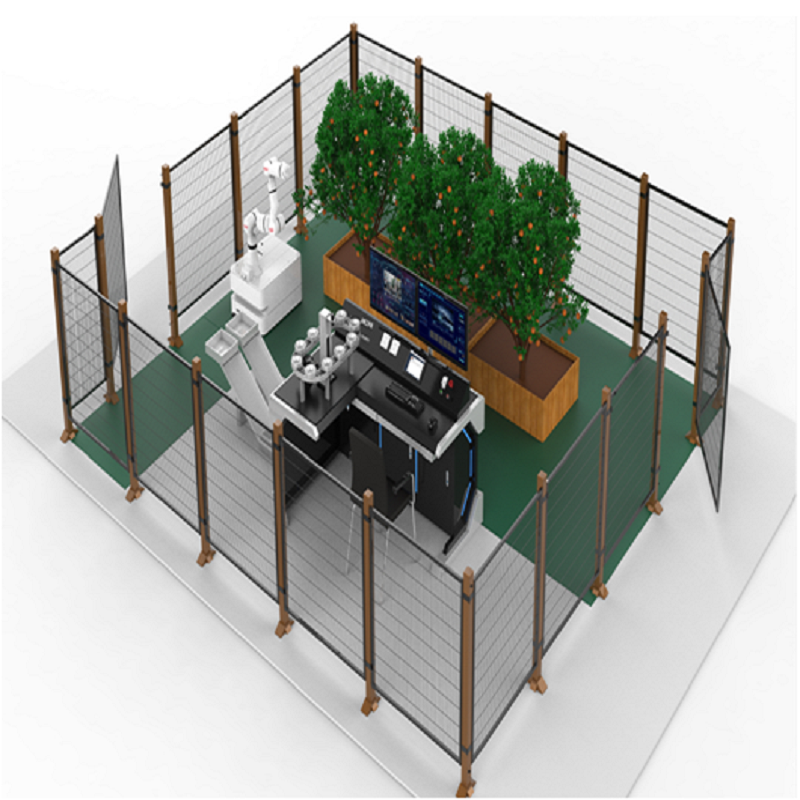

DLCIM-01 Computer Integrated Manufacturing Training System is an industry 4.0 training system and vocational training equipment, which based on industrial robots as the core, demonstration, assembly and storage of parts processing,. The device for students to provide a typical, can be integrated training system environment, to build a training platform full play to the potential of students. In the experiment, the industrial robot processing line involved in a variety of basic knowledge, professional skills and application skills can be reflected in the operation, not only to meet the requirements of professional teaching, but also can exercise students to a variety of disciplines and comprehensive use of knowledge and system thinking ability.

This training system integrate industrial robots, programmable controllers, servo motors, sensors and organic integration in one of the training system, through the signal acquisition, PLC programming, industrial robot programming, the implementing agencies for more complex switch control, position control and timing logic control, in order to achieve parts processing, assembly and storage automatic control.

2. Technical Parameter

Model: DLCIM-01

Ac Power Supply: single-phase AC220V±10% 50Hz

Temperature: -10℃~40℃; Environmental humidity: ≤90% (25℃)

Dimensions: 2810mm×1500mm×2100mm (length×width×height)

Machine Capacity: ≤1KVA

Control System: Siemens S7-1200 series PLC

Industrial Robot: MZ04-01-CFD

3. Training Projects

1. Sensor adjustment training;

2. Pneumatic connection and debugging training;

3. Servo motor control training;

4. Pneumatic connection and debugging training;

5. Robot grasping workpiece programming training;

6. Comprehensive programming debugging training;

7. Accuracy detection, debugging and principle of CNC machine tools;

8. Monitoring and compensation technology of CNC machine tools;

9. Precision debugging of CNC machine tools;

10. On-site inspection and analysis of machine tool accuracy;

11. Connection and debugging training of CNC comprehensive test bench;

12. The basic connection of the numerical control device;

13. Recognition and connection of CNC system interface;

14. Control and application of low voltage control circuit and PLC;

15. Selection and application of CNC system sensors;

16. Design principles of electrical control system for CNC machine tools;

17. Operation and debugging training of CNC machine tools;

18. PLC design and application of CNC system;

19. CNC machine tool programming and simulation processing;

20. Mastery of CNC program structure, format and instruction system;

21. Understanding of the basic processing technology of CNC machine tools;

22. CNC machine tool programming and operation and processing training;

23. Mastery of program editing of CNC machine tools;

24. Skill application of CNC machine tool system function;

25. Clamping and processing of parts in CNC machining

26. Programming and processing technology analysis of typical plane, three-dimensional graphics and other parts

27. Fault setting and diagnosis, troubleshooting

28. Fundamentals of CNC machining programming

29. Numerical control machine programming operation and processing examples

4. FAQ

Q1. What kind of price terms we can choose ?

Dolang provide EXW, FOB, CIF, CFR and other price terms based on communication.

Q2. What is the payment terms ?

TT or LC at sight, all payments are released before delivery.

Q3. What is the lead time?

Dolang provide a 50days lead time for clients, if you have special demands, pls communicate with project manager.

Q4. Whats the after sales service contents?

Dolang provide 24 hours online support for user, it is free within 1st year,

if there is no spares changes demands.