DLWD-ETBE12D730S Electrical Training Equipment Electrical Know-how Training System of vocational education equipment

- Dolang

- China

- 30-60DAYS

"DLWD-ETBE series maintenance electrician skill training system" has obtained ten national patents. It was included in the "Encyclopedia of China's Excellent Practical Patents"; it was selected by the "Hong Kong International Patented Technology Patent Products Expo" as the gold medal patent project with the most potential for transformation; the inventor was included in the book "World Contemporary Excellent Technology Experts"; the inventor was introduced by Included in "Chinese Celebrity Ceremony".

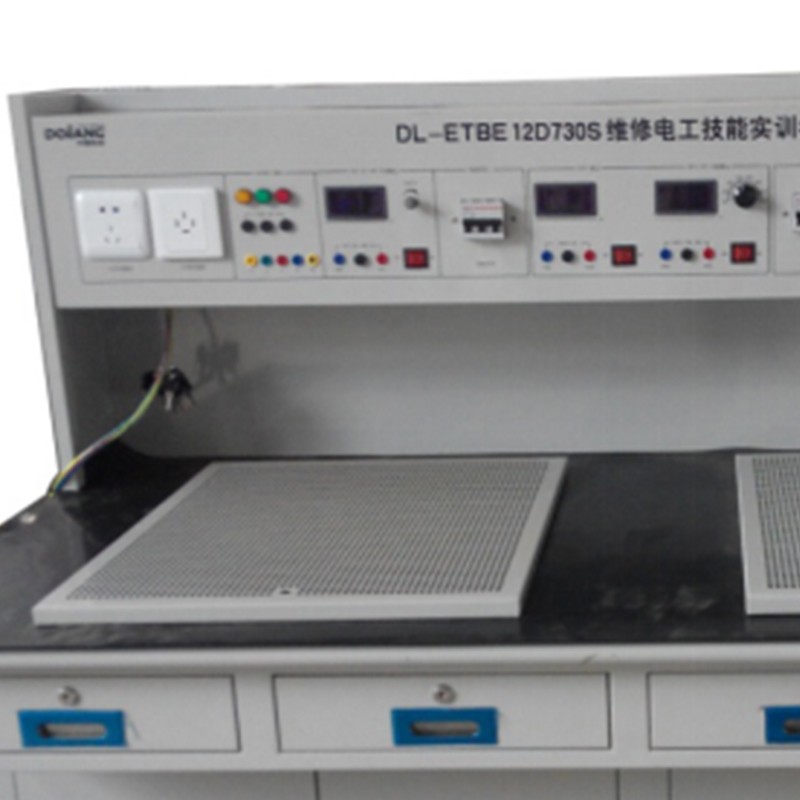

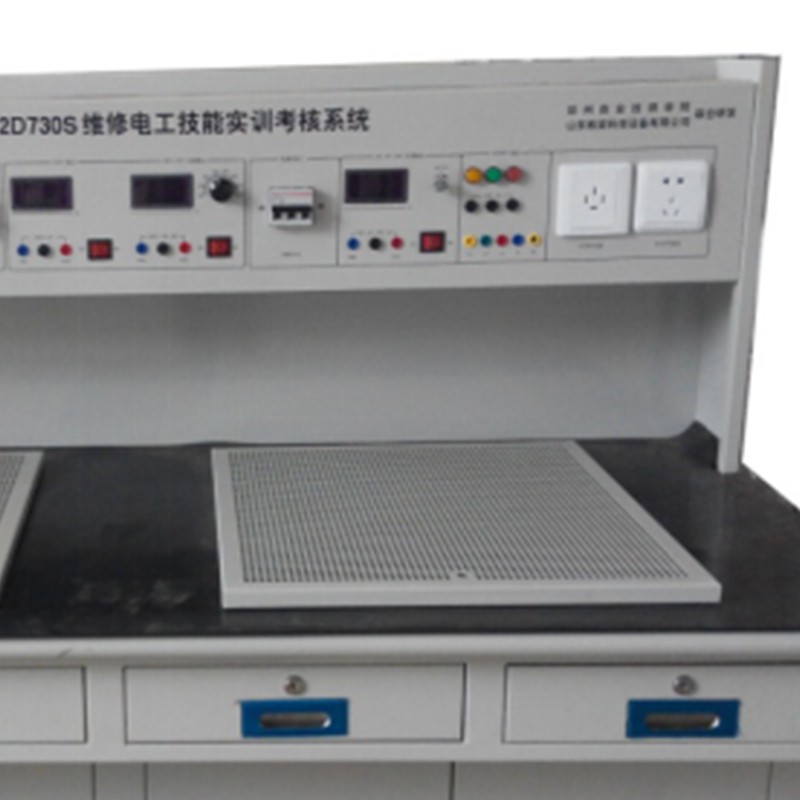

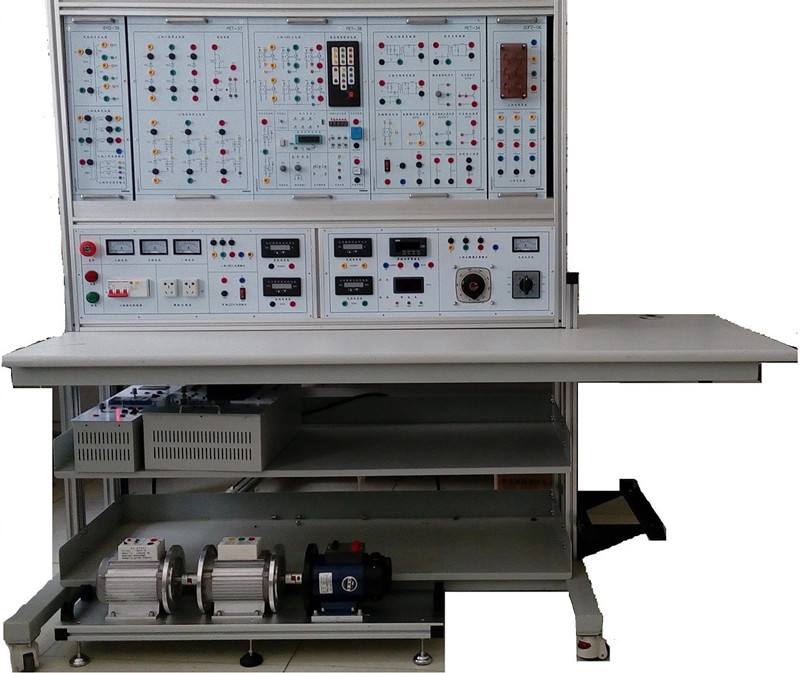

DLWD-ETBE12D730S Electrical Training Equipment Electrical Know-how Training System of vocational education equipment

Equipment Overview

"DLWD-ETBE series maintenance electrician skill training system" has obtained ten national patents. It was included in the "Encyclopedia of China's Excellent Practical Patents"; it was selected by the "Hong Kong International Patented Technology Patent Products Expo" as the gold medal patent project with the most potential for transformation; the inventor was included in the book "World Contemporary Excellent Technology Experts"; the inventor was introduced by Included in "Chinese Celebrity Ceremony".

"DLWD-ETBE Series Maintenance Electrician Skills Training System" is the closest electrician and electric drag training equipment produced in strict accordance with the German Teaching Equipment (DIN) standard.

At the same time, it satisfies students' electrical skills, installation technology, and fault analysis, and can also be used for electrical and electronic level assessment and skill appraisal. The experimental circuit can be simple or complex, from general lighting circuit to closed-loop automatic control adjustment, industrial automation system integration can be assembled on the mesh board, so that the training method is safe, standardized and has great flexibility.

Technical Parameters

1, the power input: three-phase five-wire AC380 ± 10% 50HZ ± 10%, when the input light Power output: a fuse, leakage protection switch, undervoltage and loss of voltage protection.

2, Dimensions: 160 × 80 × 80cm (L × W × H)

3, Whole capacity: ≤ 1.5kVA

4, Power control: the use of automatic air switch off power, with short circuit protection system, leakage protection system, grounding protection, emergency stop protection, etc.

Training Content

Hardware training:

⒈Circuit control and indoor wiring

①Single switch control

②Double switch control

③ Delay switch and dimming switch control

④Multi switch control

●Installation of lighting circuit

①Plastic sheathed wire wiring

②Trunk wiring

●Installation of quantity and distribution system

①Insurance method

② Wiring of single-phase watt-hour meter

③Disconnection method

⒉Power line

●Installation of power lines

①Line pipe wiring

②Bridge wiring

①Application of circuit transformer

②Three-phase three-wire watt-hour meter circuit

③Three-phase four-wire watt-hour meter circuit

3. The forward rotation control circuit of the motor

①Jog forward control circuit

②The contactor self-locking forward control circuit

③The contactor self-locking forward rotation control circuit with overload protection

④Inching and continuous mixed forward rotation control circuit

4. The forward and reverse control circuit of three-phase asynchronous motor

①Reverse switch forward and reverse control circuit

②Forward and reverse control circuit of contactor interlock

③Forward and reverse control circuit of button interlock

④Forward and reverse control circuit with double interlock of button and contactor

⑤Position control circuit (also called stroke control or limit control circuit)

⑥Sequential control circuit

⑦Multiple control lines

5. Step-down starting control circuit of three-phase asynchronous motor

① Stator winding series connection resistance step-down starting control circuit

②Manually control the compensator step-down starting control circuit

③Button, contactor, intermediate relay control compensator step-down starting control circuit

④The time relay automatically controls the compensator step-down starting circuit

⑤Manual control -△ step-down starting circuit

⑥Button, contactor control -△ step-down starting control circuit

⑦Automatic control of time relay -△ step-down starting circuit

⑧ Yanbian △ reduced voltage starting control circuit

⑨ Rotor series connection with three-phase resistance starting control circuit

⑩Button operation series resistance start control circuit

Time relay automatic control circuit

Current relay automatic control circuit

Rotor winding series connection frequency sensitive rheostat start control circuit

Cam controller circuit of wound rotor asynchronous motor

6. Brake control circuit of three-phase asynchronous motor

①Electromagnetic brake control circuit (power-off brake type and power-on brake type)

②Reverse connection of brake control circuit (one-way and two-way)

③Power consumption braking control circuit (with transformer and without transformer)

④Capacitor braking

7. Control circuit of multi-speed asynchronous motor

①The contactor controls the control circuit of the two-speed motor

②Time relay controls the control circuit of the two-speed motor

8. Control circuit of three-speed asynchronous motor

①The contactor controls the control circuit of the three-speed asynchronous motor

②The control circuit of the time relay to control the three-speed asynchronous motor

9. The basic control circuit of shunt/series DC motor

①Manual/automatic start control circuit

②Forward and reverse control circuit

③Brake control circuit (energy consumption braking, reverse braking)

④Speed control circuit (series resistance of armature circuit, change of main magnetic flux, change of armature voltage)

10. Basic control circuit of three-phase synchronous motor

①Starting control circuit (auxiliary motor starting method, asynchronous starting method)

②Brake control circuit (energy consumption braking)

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.