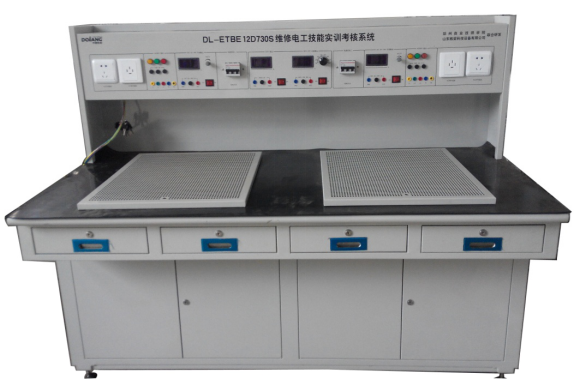

DLWD-ETBE12D-III Controlling and Switching Training System

1. The design concept adopts a desktop training platform with pendant structure, and the operating part and the control part are arranged separately.

2. The power supply part and the pendant part of the training platform are separated

3. The hanging board can be installed independently and used in combination, and the installation position can be adjusted according to the actual situation.

4. The training platform adopts three-phase five-wire access

5. The training platform can be put into use only with three-phase five-wire AC power

6. The control circuit and small motor used for skill training can simulate the electric drive system of various machinery in the factory, and can meet the skill training requirements of maintenance electrician's installation, debugging, fault analysis and elimination;

7. Some components are led to the terminals through wires, and students only need to wire on the terminals when wiring, which is beneficial to protect the components;

DLWD-ETBE12D-III Controlling and Switching Training System

Equipment Overview

1. The design concept adopts a desktop training platform with pendant structure, and the operating part and the control part are arranged separately.

2. The power supply part and the pendant part of the training platform are separated

3. The hanging board can be installed independently and used in combination, and the installation position can be adjusted according to the actual situation.

4. The training platform adopts three-phase five-wire access

5. The training platform can be put into use only with three-phase five-wire AC power

6. The control circuit and small motor used for skill training can simulate the electric drive system of various machinery in the factory, and can meet the skill training requirements of maintenance electrician's installation, debugging, fault analysis and elimination;

7. Some components are led to the terminals through wires, and students only need to wire on the terminals when wiring, which is beneficial to protect the components;

Technical Parameters

1. Technical parameters of the training platform:

1) Input voltage Three-phase five-wire system 380V±10% 50HZ

2) Working environment The ambient temperature range is -5~40℃

3), device capacity AC <1.5KVA

4) Overall dimensions: length×width×height=1810×720×1620mm

2. Total power supply control, with leakage protection function, when the leakage current reaches 30mA, the protection device will act.

3. There are 3 450V pointer type AC voltmeters for power grid voltage indication.

4. AC power supply:

(1) Provide three-phase power output

(2) 0~220V/2A adjustable AC power output

(3) Transformer AC output; the equipment has an emergency stop button, press it to immediately cut off the three-phase power output.

5. DC power supply: (1) Provide 0~30V/2A adjustable DC power supply, and equipped with DC meter display, accuracy level 1, (2) Provide 0~190V/2A adjustable DC power supply.

6. Digital instrument (1) AC digital voltmeter: measuring range 0~450V, three and a half digits display, accuracy 1.0 grade; (2) One AC digital ammeter: measuring range 0~6A, accuracy 0.5 grade, three and a half digits Display; (3) One DC digital voltmeter: measuring range 0~450V, three-digit digital display, input impedance of 10MΩ, precision 0.5; (4) One DC digital ammeter: measuring range 0~6A, three digits Semi-digital display, accuracy 0.5 level.

7. Rectifier diodes Four 1N5408 rectifier diodes are provided at the four stations for rectification and motor experiments.

Training Content

1. Electric drive training

Experiment 1 Direct start control of three-phase asynchronous motor

Experiment 2 Three-phase asynchronous motor contactor jog control circuit

Experiment 3 Three-phase asynchronous motor contactor self-locking control circuit

Experiment 4 Y-△ start automatic control circuit

Experiment 5: Contactor interlocking three-phase asynchronous motor forward and reverse control circuit

Experiment 6 Button interlocking three-phase asynchronous motor contactor forward and reverse control circuit

Experiment 7 Double interlocking three-phase asynchronous motor forward and reverse control circuit

Experiment 8 Three-phase asynchronous motor dynamic braking control circuit

Experiment 9 Sequence control of three-phase asynchronous motor

Experiment 13: Multi-site press system of three-phase asynchronous motor

Experiment eleven automatic control circuit of workbench

Experiment 12 Fluorescent lamp wiring

2. PLC control training

Training 1: PLC control motor jog and self-locking control

Training 2 PLC controlled motor manual forward and reverse control

Training three: PLC control motor with delay forward and reverse control

Practice 4 PLC control motor start and stop control in two places

Practical training 5 PLC control motor sequence control

Training 6 PLC control motor star/delta start automatic control

Practice 7 PLC control motor star/delta start manual control

3. Inverter control technology training

Training 1: The basic operation and parameter setting of the inverter

Training 2: Inverter stepless speed regulation

Training three external terminal jog control

Training four: inverter controls the motor forward and reverse

Practice 5 Multi-speed selection frequency conversion speed regulation

4. Touch screen screen editing and function debugging

Training one basic configuration training project

Training 2 Motor Star Delta Configuration Training Project

5. Machine tool assessment and training

Training one CA6140 lathe training instructions

Training two X62W milling lathe training instructions

Practice training 3 Use DLWW-GX2.0 network intelligent wireless communication assessment and appraisal management system operation

6, PLC execution object training

Training 1: PLC controlled stepper motor jog operation

Training 2: PLC controls the steering and speed of the stepper motor

Training three: parameter setting and debugging of AC servo system

Training four: parameter setting of AC servo motor driver

Training 5 PLC controls the steering and speed of the servo motor

Training 6 Comprehensive operation of PLC control servo system

Practical training 7 PLC programming and debugging of automatic feeding and loading module

Training 8: Programming and debugging of PLC program for liquid mixing training module

Practical training 9 Four-floor elevator module PLC programming and debugging

Practical training ten water tower water level module PLC programming and debugging

Training 11: Programming and debugging of PLC program for mail sorting module

Twelve training sessions: Programming and debugging of PLC program for the light module of Tianta

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.