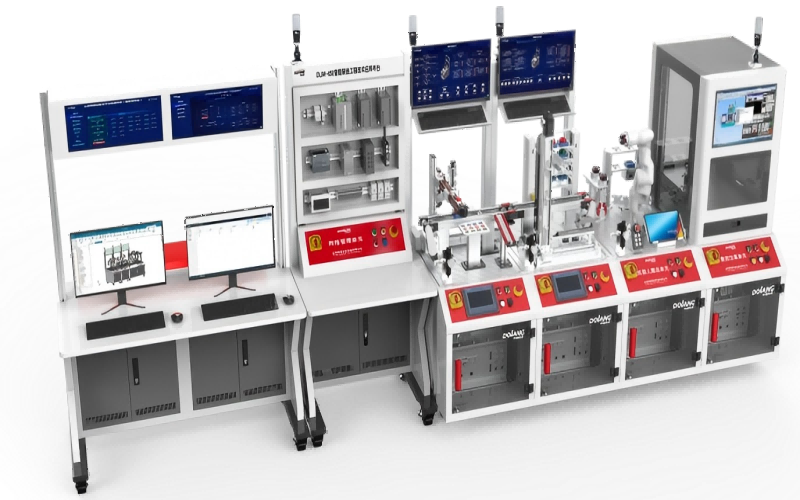

DLMPS-205 Modular Flexible Production System of vocational education equipment

- Dolang

- China

- 30-60DAYS

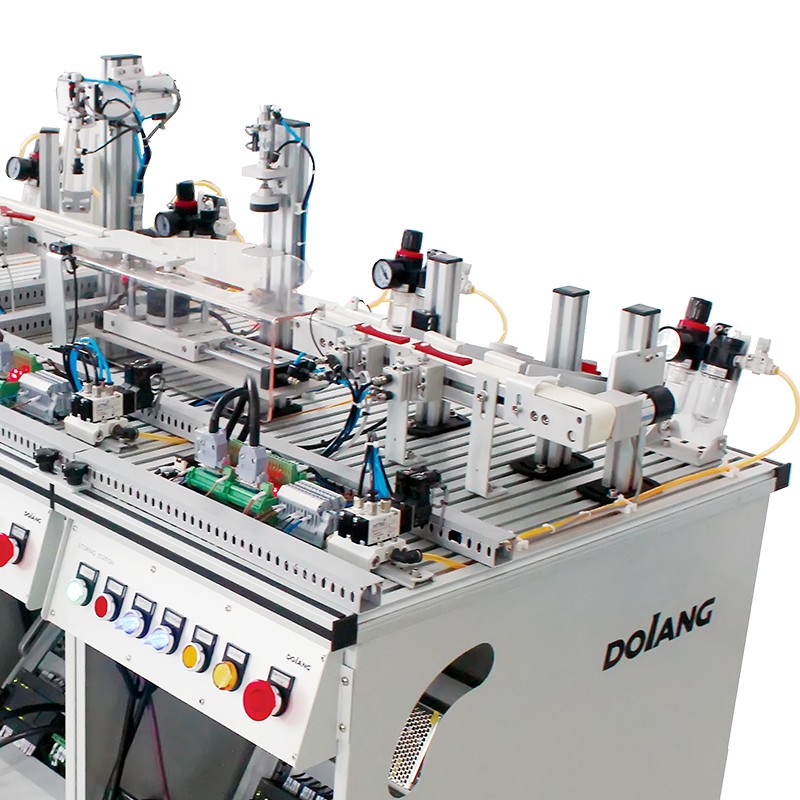

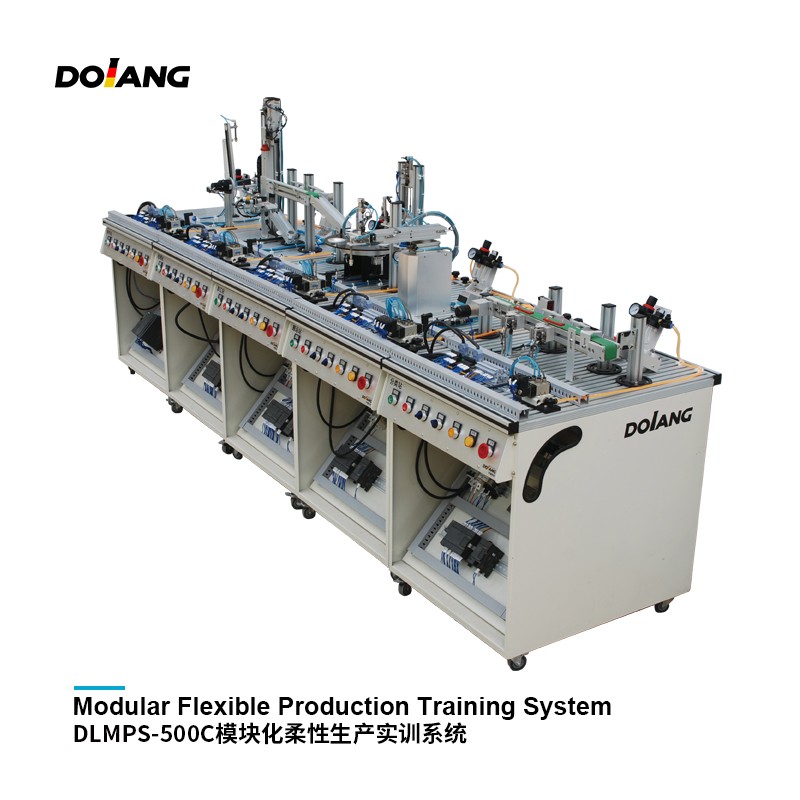

The DLMPS-205 flexible manufacturing training system consists of a feeding station, a testing station, a handling station, an extrusion station and a sorting station. Each station is installed on a slotted aluminum substrate, and each station can be easily connected together to form an automatic Processing production line. Each station is a modular structure, each module is easy to build, disassemble and maintain, and each workstation can be combined at will.

DLMPS-205 Modular Flexible Production System of vocational education equipment

Equipment Overview

The workpiece in the silo is supplied, and the suction cup transfers the workpiece from the feeding station to the inspection station.

The sensor detects the color and material of the workpiece, the lifting cylinder (sliding table cylinder) rises, and the height measuring cylinder goes down. After the photoelectric sensor measures the height of the workpiece, the height measuring cylinder goes up and the lifting cylinder goes down. In the case of finished product (middle height): the cylinder pushes the workpiece to the transfer station, starts the extrusion station motor, and sends the color signal to the sorting station. In the case of defective products (high and low): the lifting cylinder descends, the cylinder pushes the waste to the lowering trough, returns to the initial position, and the feeding station continues to feed.

After a period of conveyance, the workpiece reaches the stop position. When it arrives, the manipulator sucker sucks up the lid and places it on the workpiece. After completion, the stopper cylinder releases the workpiece, and the belt conveys the workpiece to the extrusion station.

When the extrusion station receives the workpiece, the conveyor belt motor stops running, and the stopper cylinder returns to its original position. When the extrusion station receives the workpiece, the transport arm moves the workpiece to the extrusion position, the extrusion cylinder presses down, and the cover is pressed into the workpiece. After completion, move the workpiece to the position aligned with the sorting station, and then move the sliding table cylinder to the right to push the processed workpiece to the sorting station. When the sliding table cylinder reaches the right position, start the sorting station belt motor.

When a workpiece is detected at the entrance of the classification station, combined with the color signal of the monitoring station, if it is silver, the No. 1 cylinder moves and the workpiece slides into the No. 1 slot; if it is red, the No. 2 cylinder moves and the workpiece slides into the No. 2 slot; If it is black, the No. 1 and No. 2 cylinders will not act, and the workpiece will slide directly into the No. 3 slot. When the warehousing signal detects the workpiece, the belt motor will stop and the cylinder will return to its original position.

Technical Parameters

1. The power supply of the main circuit of the electric control cabinet: single-phase AC220V±10% 50Hz;

2. Power supply for the control loop of the electric control cabinet: DC24V

3. Temperature: -10℃~40℃; Environmental humidity: ≤90% (25℃);

4. Dimensions: 450mm×770mm×1100mm

5. Air source pressure: 0.4~0.6Mpa

6. Machine capacity: ≤1KVA

Training Content

1. Cognition and application of pneumatic technology

●Understanding of air pump

●Awareness of air source processor

●The perception of filters

●Awareness and application of vacuum generator

●Awareness of various cylinders (pen-type cylinder, double-axis cylinder, rotary cylinder, etc.)

●Awareness and application of solenoid valve

●Recognition and application of magnetic switch

●Connecting cognition of trachea

●Cognition of adjusting joints

●Installation and debugging of solenoid valve

●Installation and debugging of cylinder

●Installation and debugging of air motor

●Installation and debugging of air source treatment

●Maintenance and maintenance of various cylinders

●Maintenance and maintenance of various solenoid valves

2. Cognition and application of sensor technology

●Cognition and application of photoelectric sensor

●Cognition and application of optical fiber sensor

●The cognition and application of magnetic sensor

●Cognition and application of current sensor

●Wiring method of various sensors

●Failure judgment and maintenance of various sensors

●Wide application of various sensors in industrial scene

3. Cognition and application of mechanical transmission technology

●Cognition and application of belt transmission

●Cognition and application of gear transmission

●Awareness and application of cylinder transmission

4. The principle and application of industrial automation technology

●The principle and application of PLC

●PLC programming method and application

●PLC program for feeding station

●PLC program for testing station

●PLC programming transfer station

●PLC programming of extrusion station

●PLC programming classification station

●PLC network programming method

●Comprehensive programming method for each station

5. Cognition and application of automated production lines

●Application of feeding station

●Application of inspection station

●Application of handling station

●Application of extrusion station

●Application of classification station

●Relations and applications between stations

●Practical training of systematic comprehensive ability

FAQ

Q1. What other services can Dolang provide besides teachingequipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.