DLDS-124 Digital Twin Technology Application System Technical Document

Digital twins make full use of data such as physical models, sensor updates, and operation history, integrate multi-disciplinary, multi-physical, multi-scale, and multi-probability simulation processes, and complete mapping in virtual space to reflect the entire life cycle of the corresponding physical equipment. Digital twins are a concept that transcends reality and can be viewed as a digital mapping system of one or more important, interdependent equipment systems.

Equipment Overview

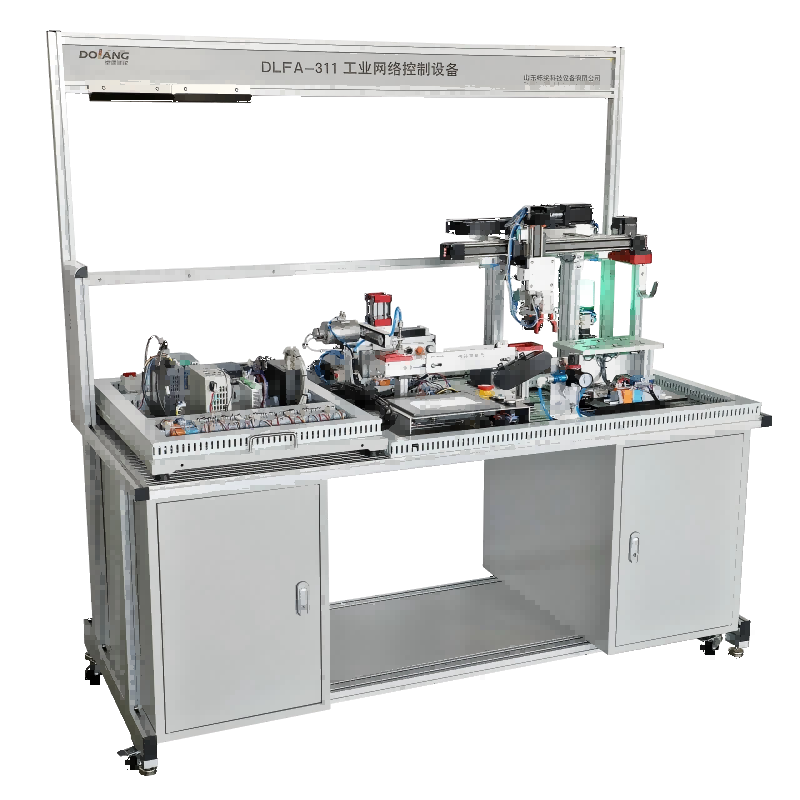

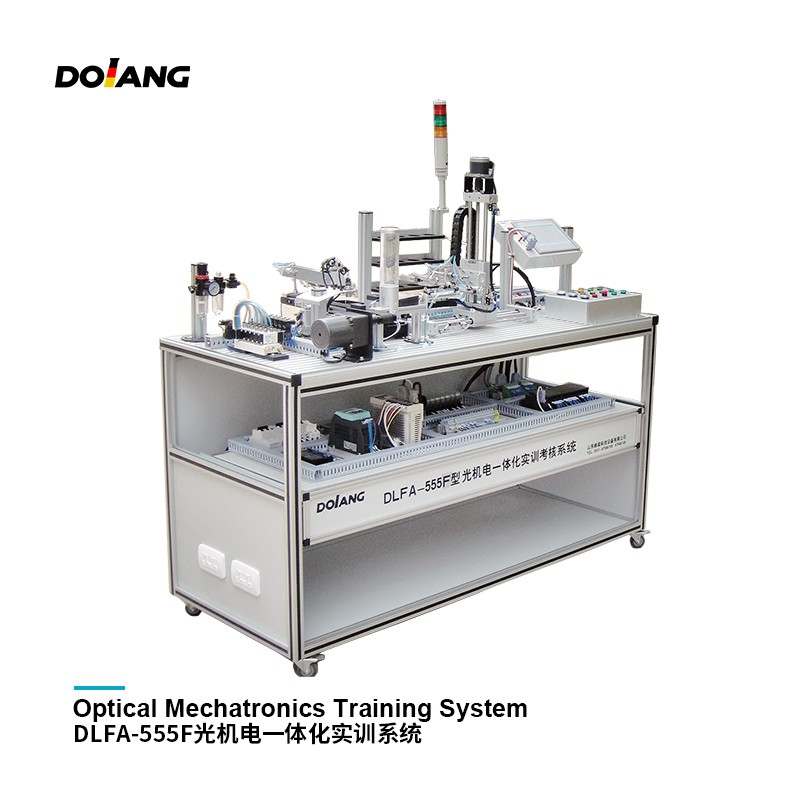

Of the DLDS-124 digital twin technology application system includes a material box feeding unit, a height detection unit, a steel ball feeding unit, a material color detection unit, a material cover assembly unit, a storage unit, and a transportation unit. The system can complete the process of feeding, testing, filling, assembly, testing, and warehousing, and realize virtual-real linkage through digital twin software .

Technical Parameters

(1) Input power: single-phase three-wire, AC220V±10%, 50HZ 50HZ

(2) Output power: DC24V 5A

(3) Machine capacity: about 1.0 KW

(4) Working environment: temperature 0℃-40℃, relative humidity <85% (25℃), no condensation, altitude <4000m

(5) Recommended working air pressure: 0.4 -0.6 MPa .

Training Content

(1) Detection technology: Students can learn about various sensors on this equipment and master how to use them.

(2) Control system: Students can learn circuit principle analysis and equipment circuit analysis methods on this equipment.

the use of stepper motors on this equipment .

(4) Siemens PLC technology: Students can practice PLC wiring, programming, and debugging on this equipment.

(5) Configuration technology: Students can practice programming with Siemens configuration software and communication between configuration software and PLC on this device.

( 6 ) System maintenance and fault detection technology: Trainees can practice the content and methods of daily equipment maintenance as well as common fault analysis and troubleshooting methods on this equipment .

( 7 ) Digital twin technology: digital model construction and layout, virtual debugging, virtual production line rhythm optimization, etc.

FAQ

Q1. What other services can Dolang provide besides teaching equipment?

Answer: Curriculum standard, teacher courseware (PPT), teaching equipment training list, examination question bank, classroom task list, students' books (learning materials), teaching software, etc

Q2. What kind of certification?

Three system certification ISO9000, ISO14001, OHSMS28001; CE certification, SGS certification and Dolang are gold medal members of worlddidac.

Q3. What can Dolang do for our teachers?

Answer: a) Dolang group has Shandong Dolang vocational school, which is specially responsible for the training of teachers. Our national teacher training courses and provincial teacher training courses all cooperate with Dolang school;

B) Dolang has a large number of Chinese vocational college resources, which can also be used for teacher training in your country.

Q4. What kinds of training methods will Dolang provide?

1. We supply you detailed manual books, video and online training service.

2. We supply you training at site, we can send engineer to your place for training

3. You can send your people come to Dolang for training.