MRSP ANNUAL CONVENTION 2021-2022 Theme: Breakthrough Innovation, Creativity and Resilience

MRSP ANNUAL CONVENTION 2021-2022

Theme: Breakthrough Innovation, Creativity and Resilience

by Embracing Change and Transformation through Research on February 25-26

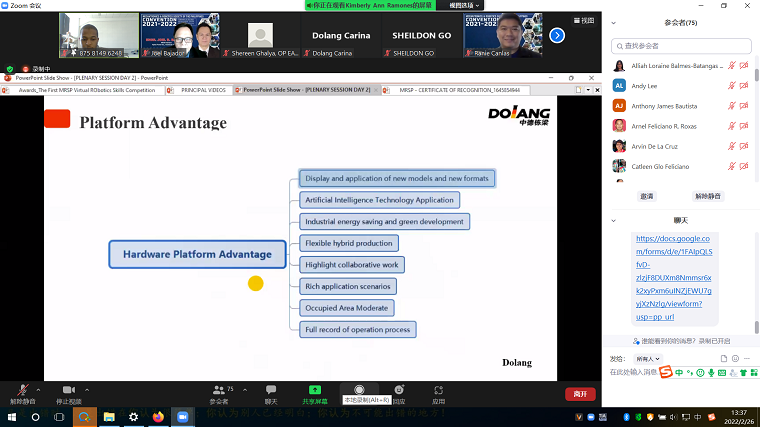

Dolang participanted the MRSP ANNUAL CONVENTION 2021-2022 on Feb 25-26th in order to promote the international cooperation of vocational education between China and Philliphines.

Dolang presented WorldSkills China – Robotic System Integration Application Technology. The MRSP and TESDA like the Robot Systems Integration system from Dolang very much.

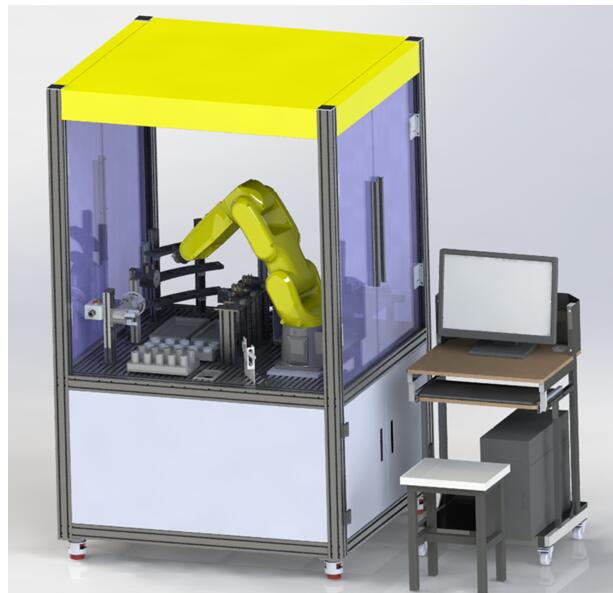

DLDS-1190 Industrial Robot System Integration Platform

DLDS-1190 industrial robot system integration platform takes FANUC LR-Mate 200iD industrial robot, SIEMENS S7-1500 CPU1516-3 PN/DPPLC as the main body, with FANUC industrial intelligent camera vision system (2D), grinding machine unit, analog CNC machining unit, Material assembly unit, material handling unit, plane trajectory training unit, surface trajectory unit, space trajectory training unit, drawing puzzle unit, automatic cup supply unit, gantry detection unit, sensor detection and positioning unit, three-dimensional warehouse storage unit, cache unit, tools Coordinate calibration unit, etc. This platform can train students to master the operation, debugging, visual application of industrial robots, PLC principle, PLC programming, sensor technology, Profinet industrial Ethernet communication technology, etc.

Training content:

1) Installation of industrial robot

2) Installation of industrial robot teach pendant

3) Installation of end tool of industrial robot

4) Setting of industrial robot parameters

5) Practical training of industrial robot operation mode and manual speed

6) View common information of industrial robots

7) Introduction of industrial robot programming instructions

8) Backup and recovery of industrial robot programs

9) Initial power-on and IO configuration of the industrial robot

10) Practical training for the calibration of industrial robot coordinate system

11) Setting of safe working area of industrial robot

12) Industrial robot fault diagnosis and maintenance

13) Practical training in reading electrical drawings

14) Pneumatic circuit connections and electrical wiring

15) Application of detection switch

16) Application of various sensors

17) Application of pneumatic components

18) Installation and application of PLC

19) Installation and application of touch screen

20) Communication between robot and PLC

21) Communication between touch screen and PLC

22) Practical training of industrial robots and visual communication

23) Application of industrial robot quick change tool